| Imaging Group |

|

The XSD Imaging Group operates, maintains, and advances capabilities for three beamlines that service five end stations (2-BM-A/B, 7-BM-B and 32-ID-B/C). The upstream station 2-BM-A is dedicated to high-speed tomography and includes a white/pink-beam fast tomography system while the downstream station includes a monochromatic/pink-beam, high-resolution tomography system. The fast tomography system provides sub-second tomography and is the ideal tool for three-dimensional (3-D) in situ dynamic studies in materials science and biology. The 2-BM-B tomography system provides a reliable and easy-to-use system that is able to determine the distribution of physical quantities (density, porosity distribution, crack size, etc.) in 3-D on a large population of samples. This system is routinely used for material science, battery research and biological studies. The 7-BM-B station is dedicated to hard x-ray tomography with filtered BM white beam, high-speed white beam imaging, and focused beam radiography and fluorescence spectroscopy. The beamline caters to the multiphase flow and combustion communities and is uniquely equipped for these communities. The beamline features a high-capacity compressed air supply (200 scfm at 110 psig pressure) with an air receiver to accommodate blowdown operations. This air supply is critical for measurements of shear-atomization for the gas turbine and high-speed flow communities. The beamline is also capable of 30 x 3 mm (H x V) wide-field with filtered white beam, which complements the smaller, higher-flux beam provided by 32-ID. The 32-ID beamline services two end stations hosting the high-speed x-ray imaging/diffraction and transmission x-ray microscopy programs. The high-speed x-ray imaging/diffraction program requires and uses the unique single-pulse brightness and timing structure of the APS for single-shot, 100-ps exposures ideally combined with megahertz frame rates. The wide energy range allows for the study of fast dynamic processes in soft as well as hard materials. The transmission x-ray microscopy program is equipped with the highest performance sub-10-nm spatial resolution hard x-ray transmission x-ray microscopy in the world, and it is optimized for in situ microscopy/tomography of energy-research-related materials. The Imaging Group instruments are among the highest data-volume producers at the APS and are at the leading edge of development of standardized data formats and automated data handling through an extensive worldwide network including other synchrotron facilities and the DOE, Argonne, and University of Chicago advanced computational resources. |

| 2-BM-A,B (XSD) High-Speed Tomography |

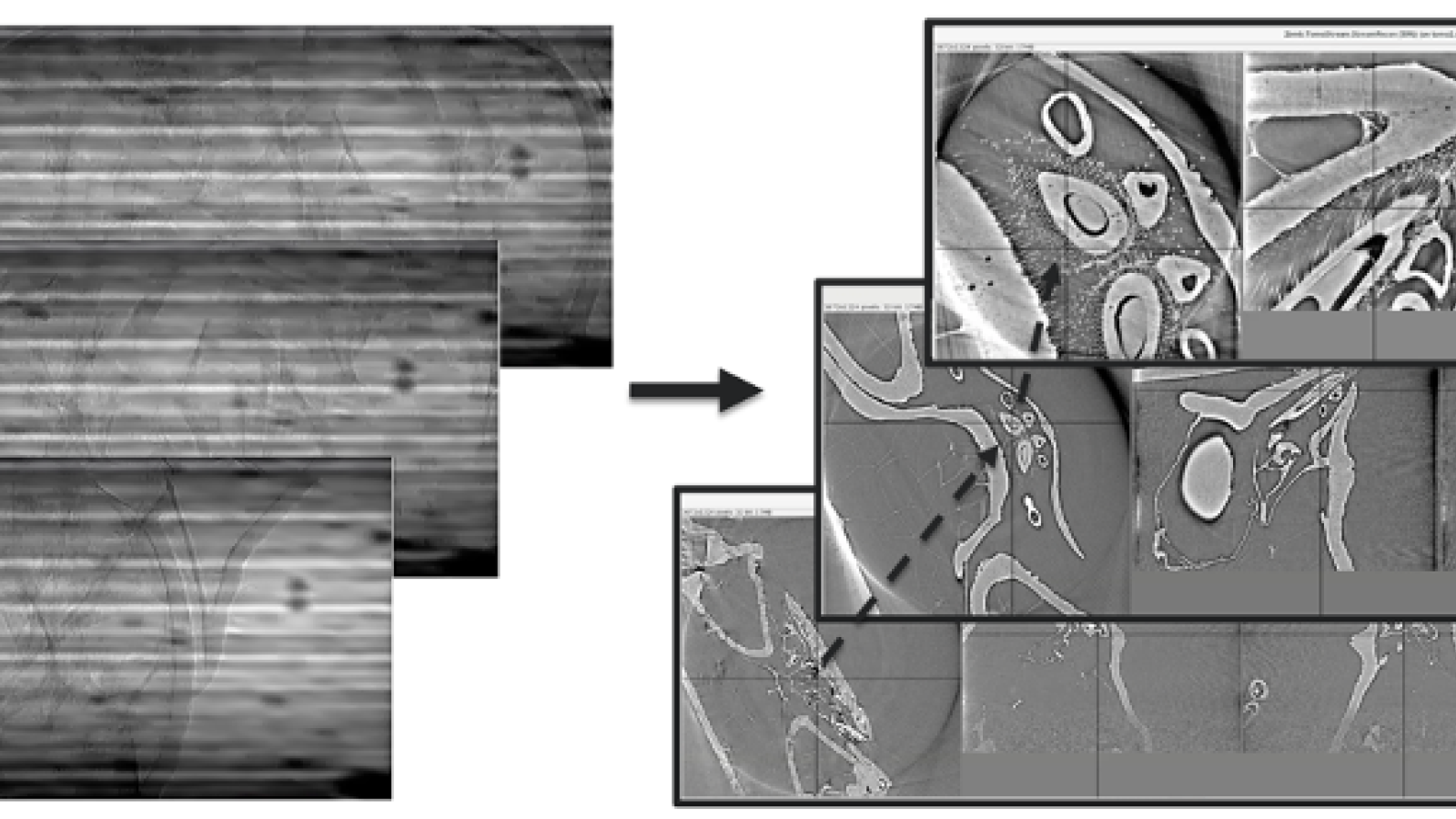

| The 2-BM-A,B beamline hosts a dedicated parallel-beam micro tomography program. Major design improvements to meet user demand and to provide superior analytical imaging performance and in situ capabilities include: (1) designed and implemented a new standardized control system (TomoScan) that supports step & fly & interlaced scans and streaming data collection for tomography. This systems now runs at 2-BM, 7-BM, and 32-ID allowing for fast propagation of new features and improvements with lower maintenance effort; (2) designed and implemented a new real-time tomography reconstruction code (TomoStream) to support streaming data collection; (3) designed and implemented a new command-line-interface (tomopy-cli) to better support our tomography reconstruction software (tomopy); (4) installed and tested a new Adimec camera for fast data acquisition; (5) installed a new gas pump system for in-situ experiments with high-pressure conditions; |

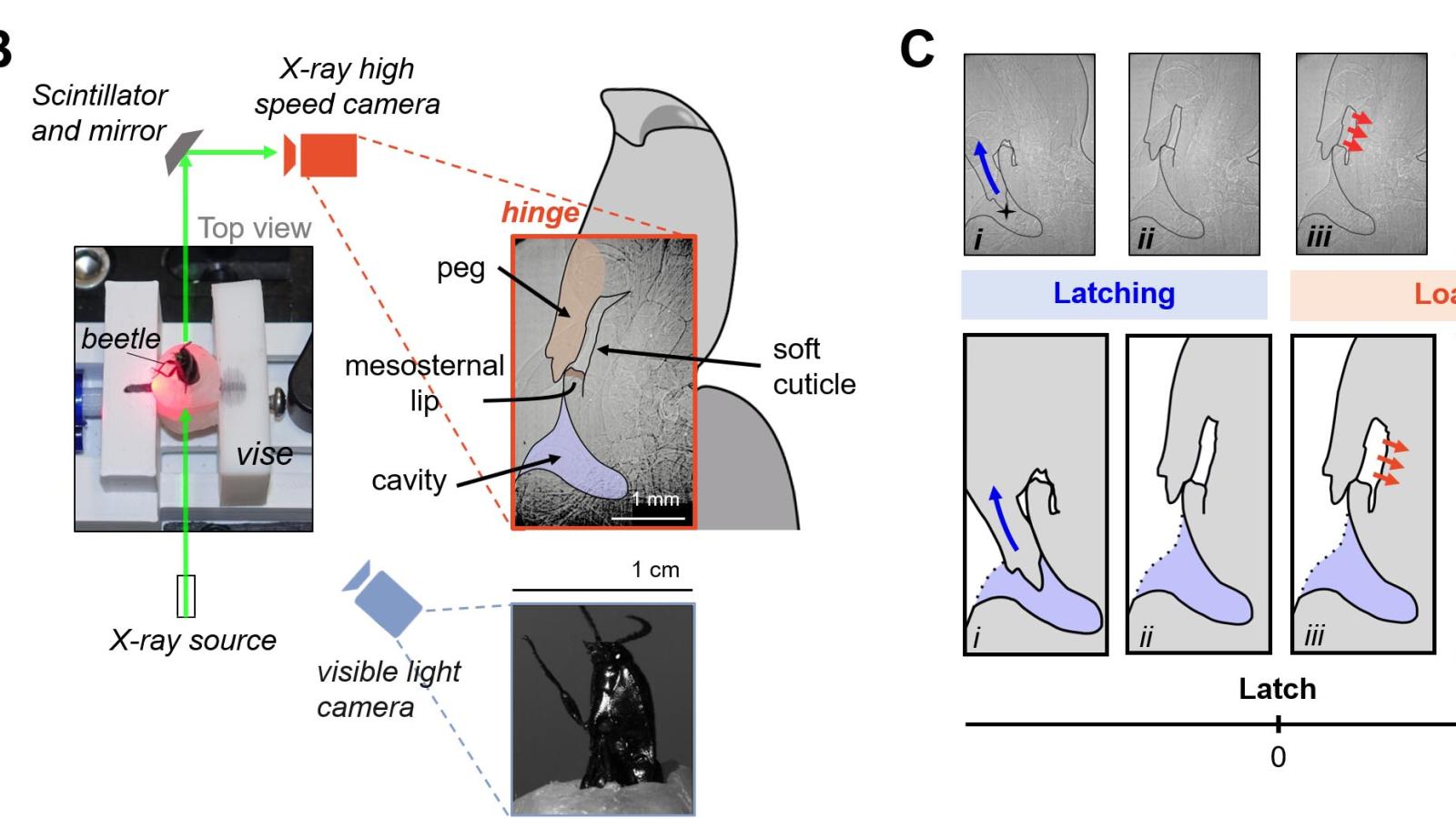

| 7-BM-B (XSD) Complex Fluid Dynamics |

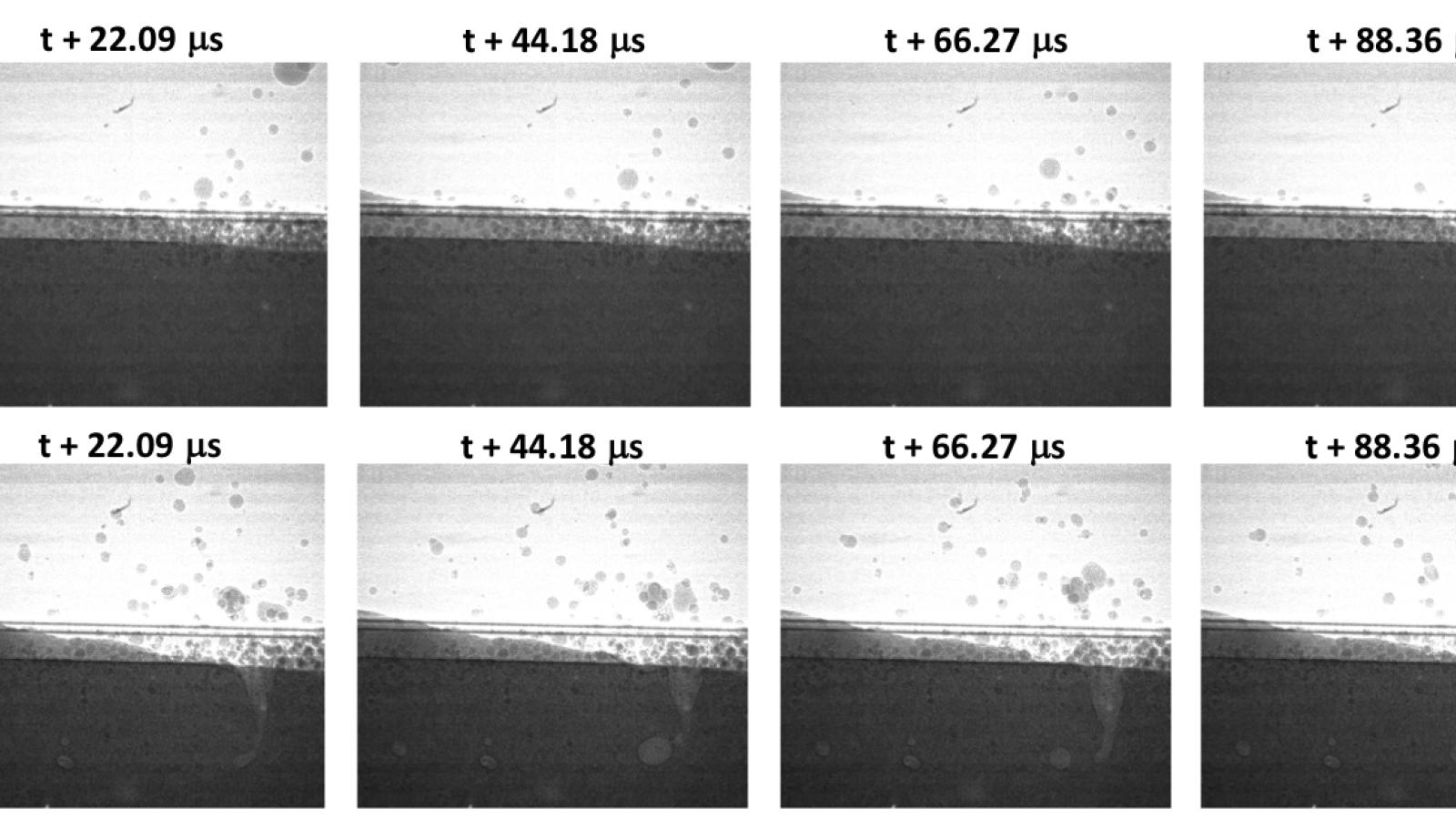

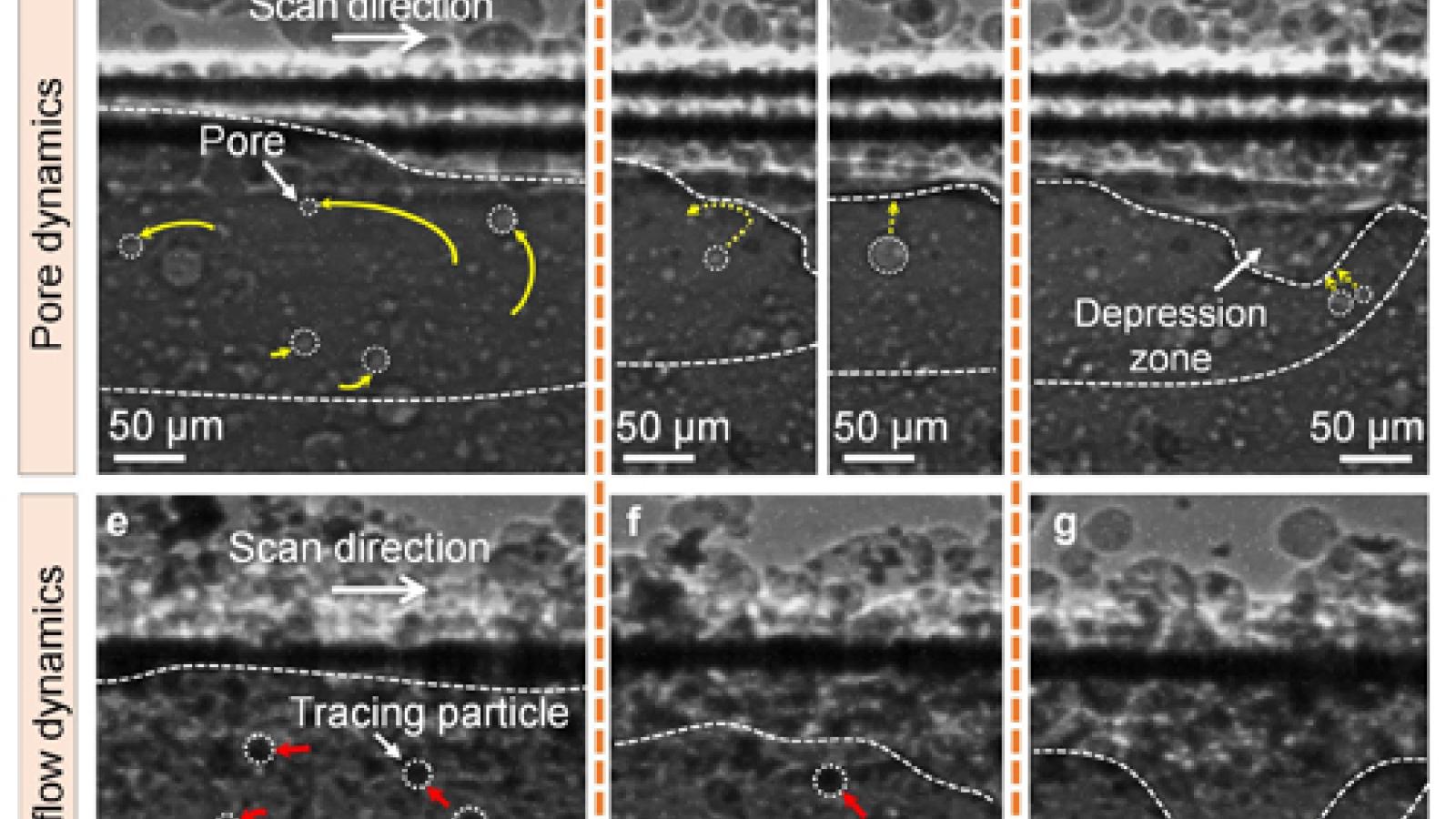

| A major improvement to 7-BM from 2017-2020 has been the addition of a high-capacity compressed air supply (200 scfm at 110 psig pressure), including an air receiver tank to permit blowdown operations for higher flowrates at shorter runtimes, funded through 7-BM users and internal investments. This capability is unique at the APS and has been instrumental for a number of experiments at 7-BM, including high-speed imaging and radiography of a canonical shear atomizer (DOI: 10.1016/j.ijmultiphaseflow.2020.103219), high-speed imaging of gas turbine combustor flow (DOI: 10.2514/6.2020-0522), and operation of a small-scale supersonic wind tunnel (DOI: 10.1615/AtomizSpr.2020034448). A further improvement to the beamline has been the commissioning of a multilayer mirror housed in 7-BM-B. This mirror provides considerable energy flexibility to the beamline, allowing for x-ray fluorescence measurements of elements through the lanthanides. This has been used by users to study multiphase flow structure in internal flows in aluminum nozzles (DOI: 10.2514/6.2020-0355). |

| 32-ID-B (XSD) High-speed X-ray Imaging/Diffraction |

|

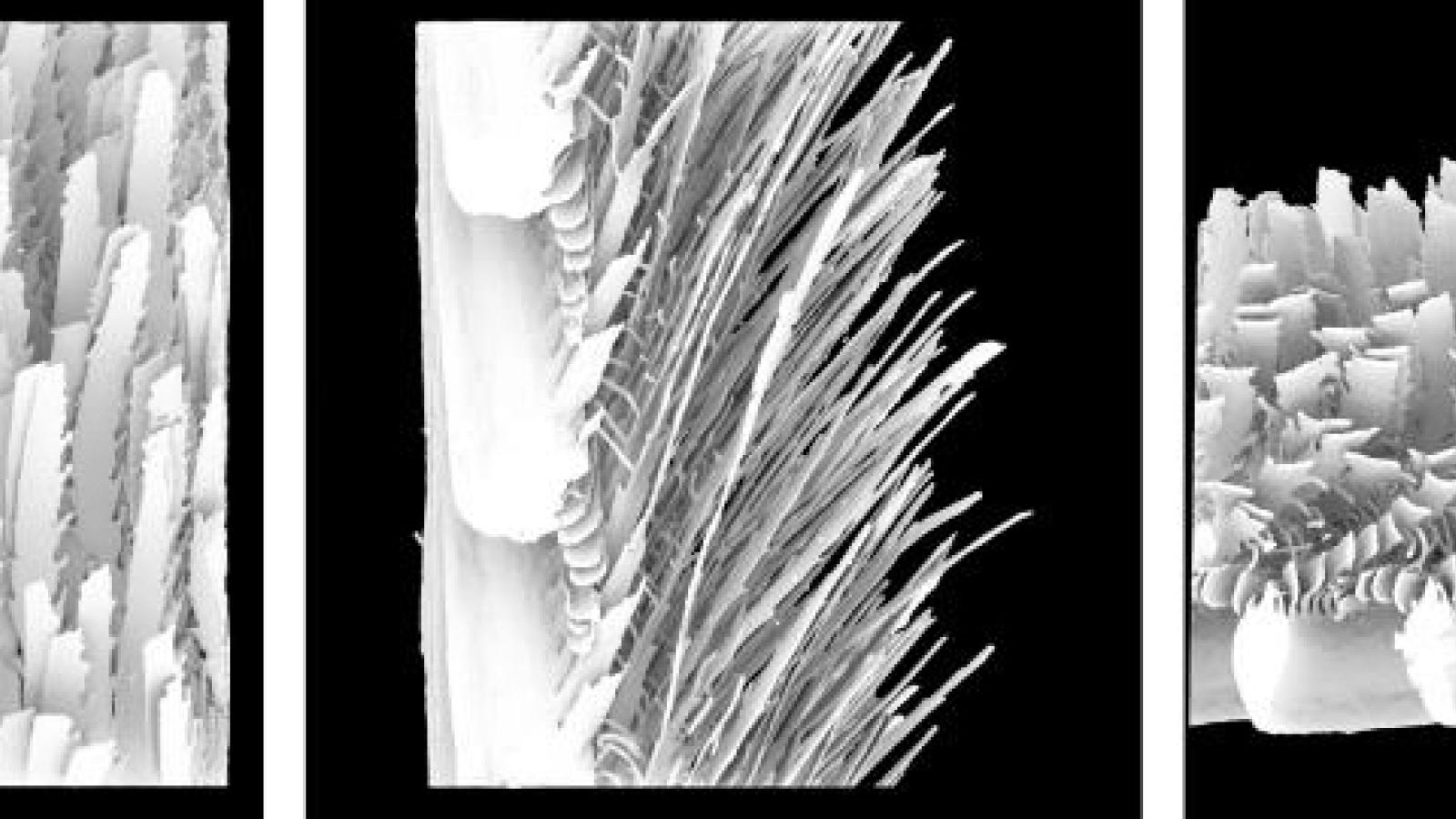

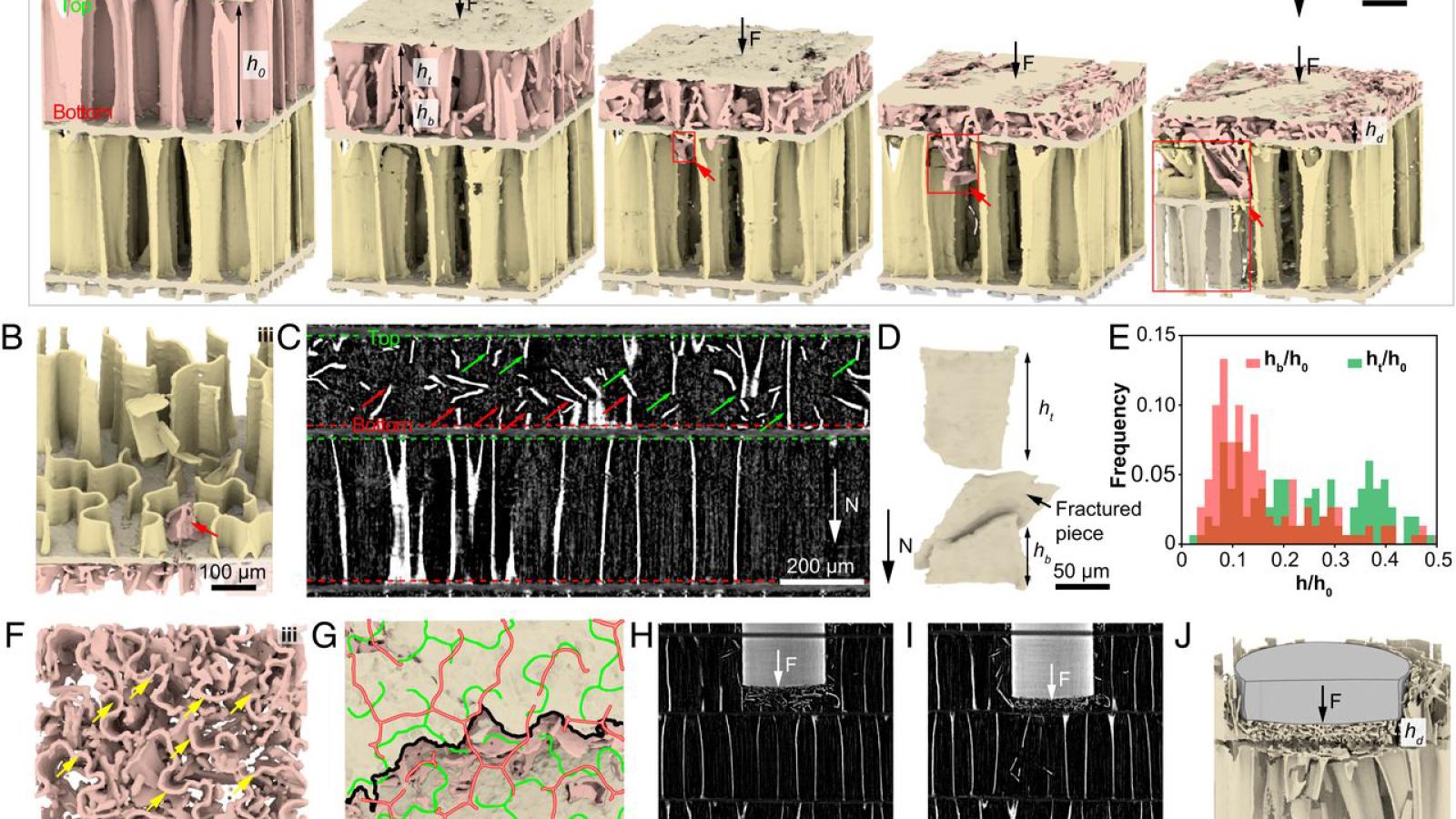

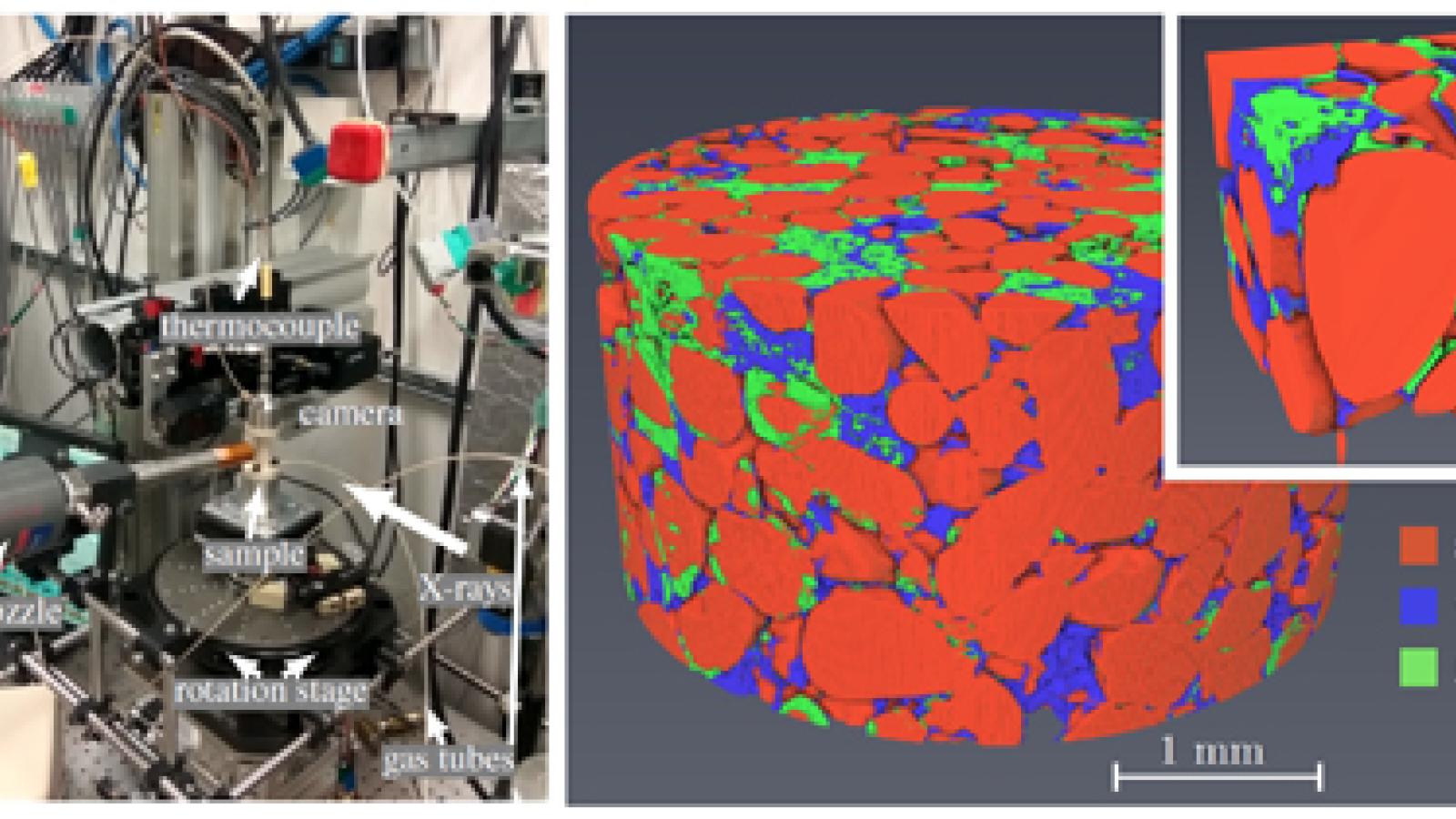

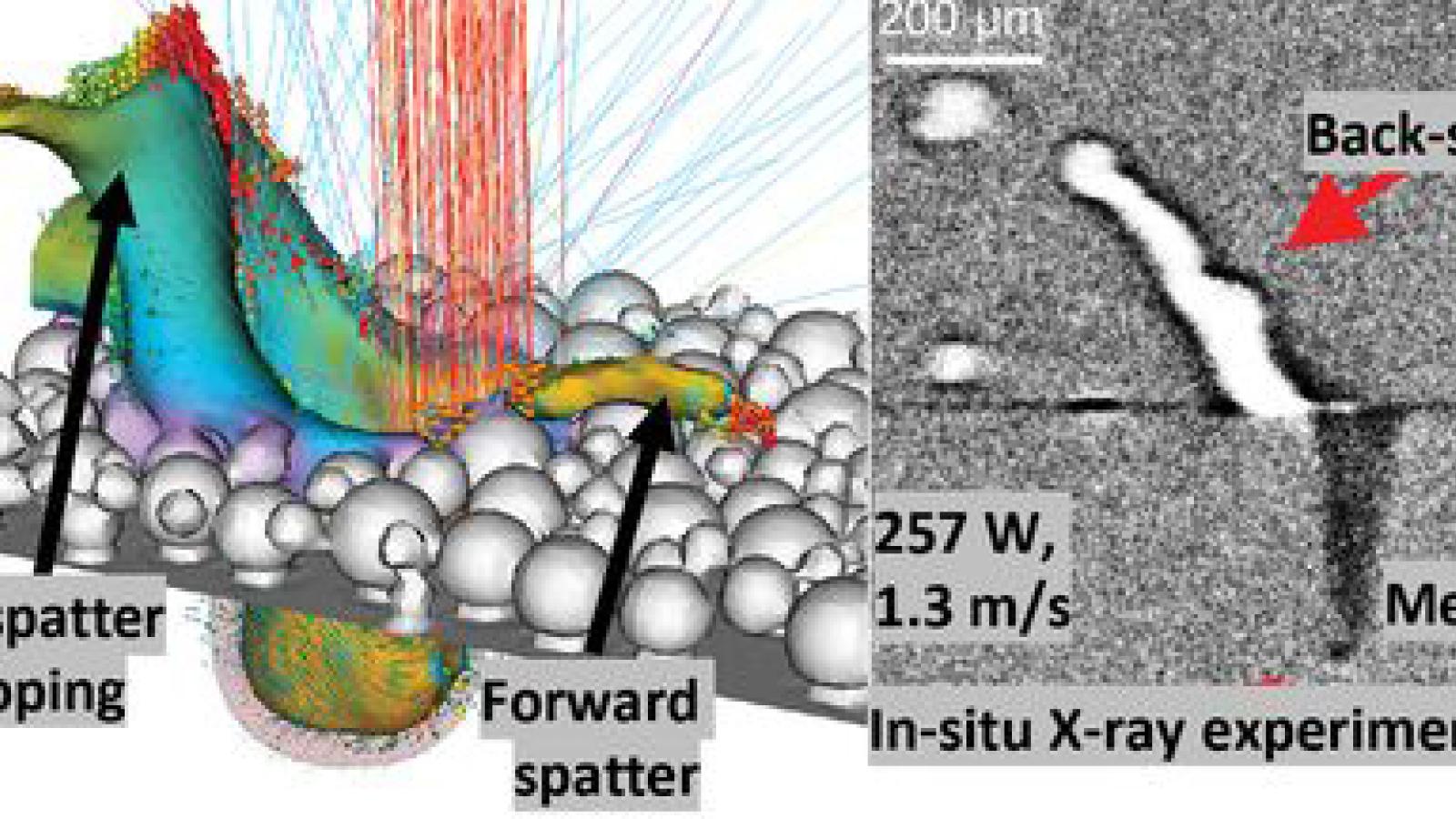

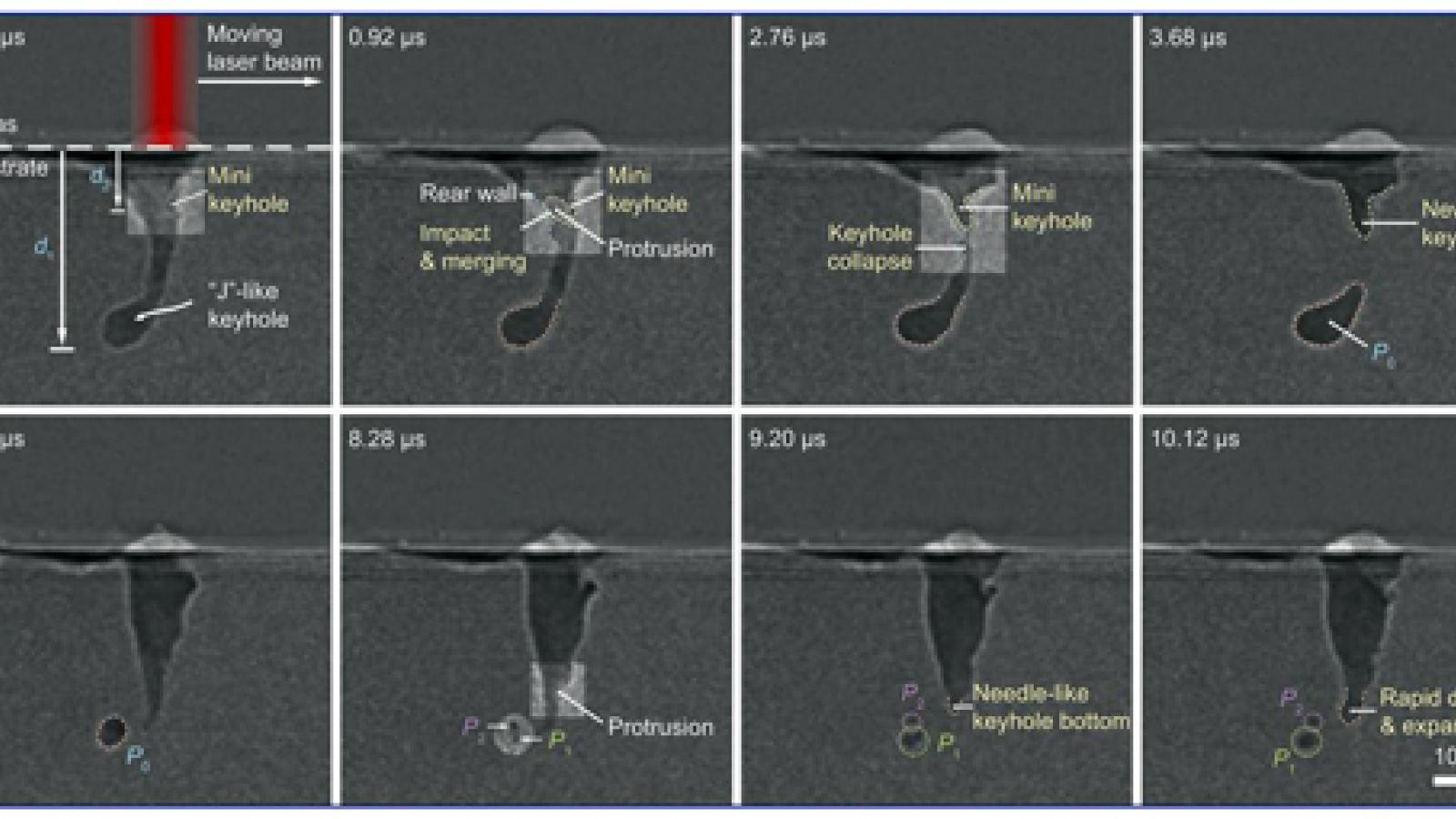

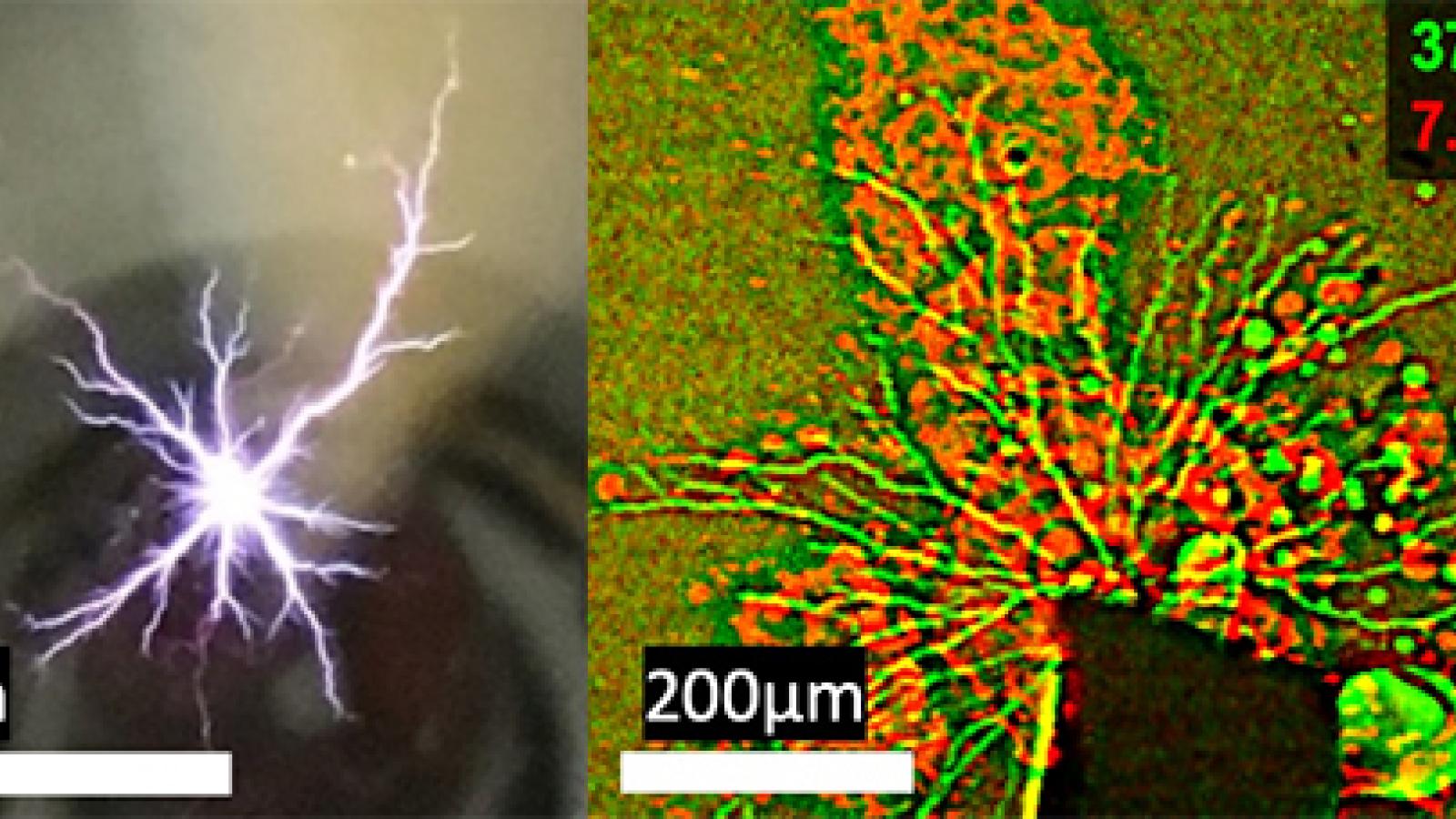

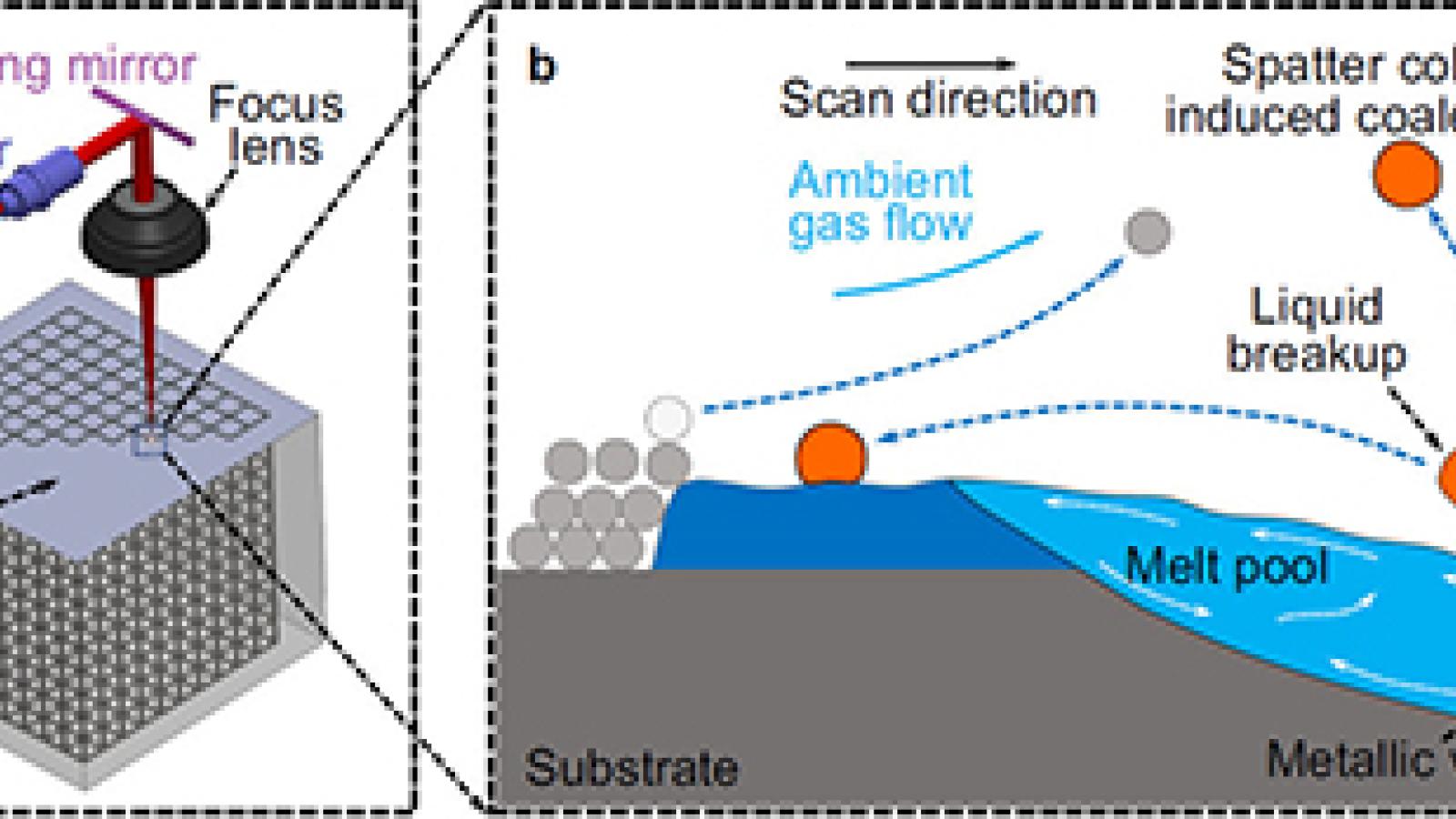

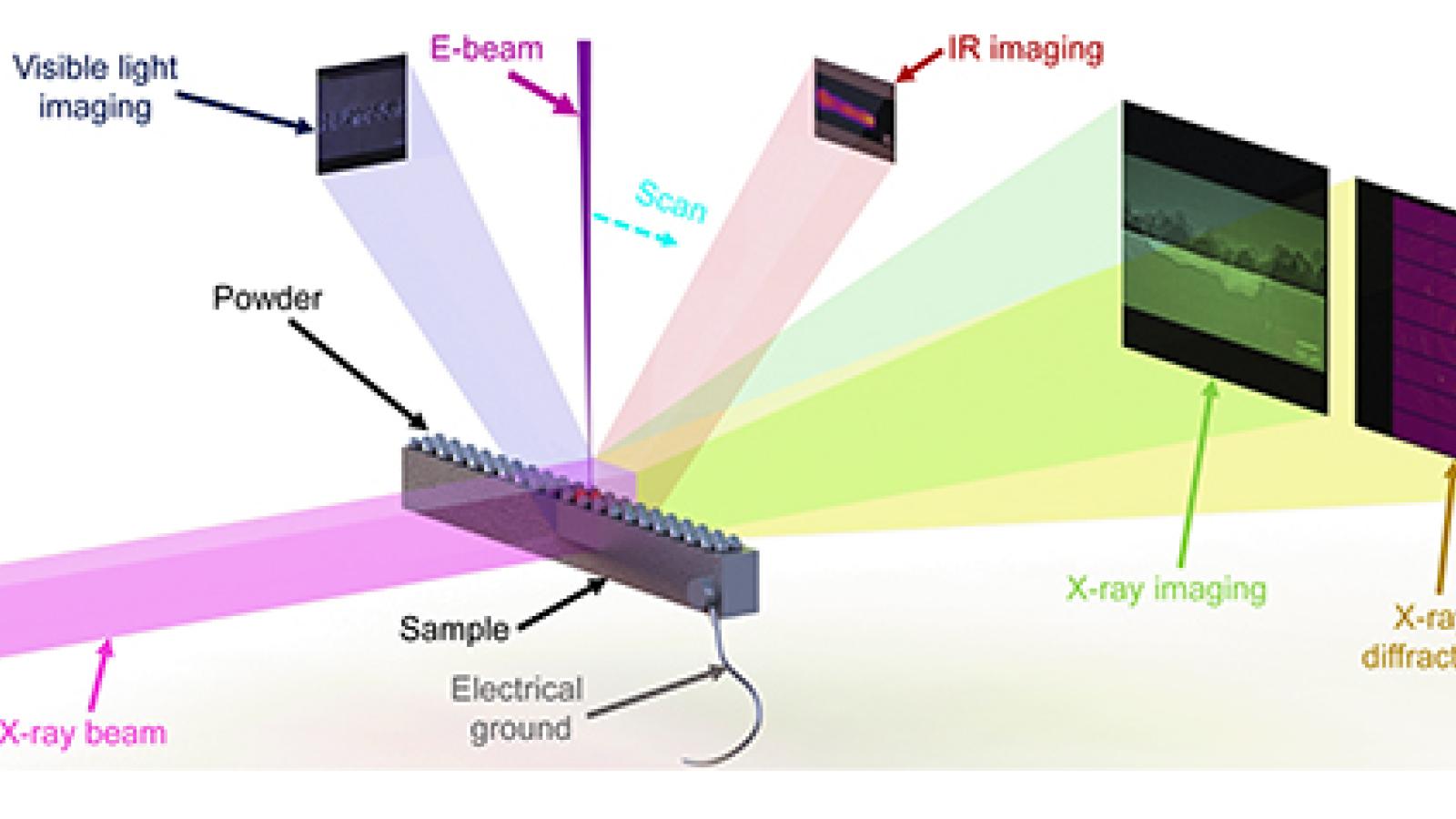

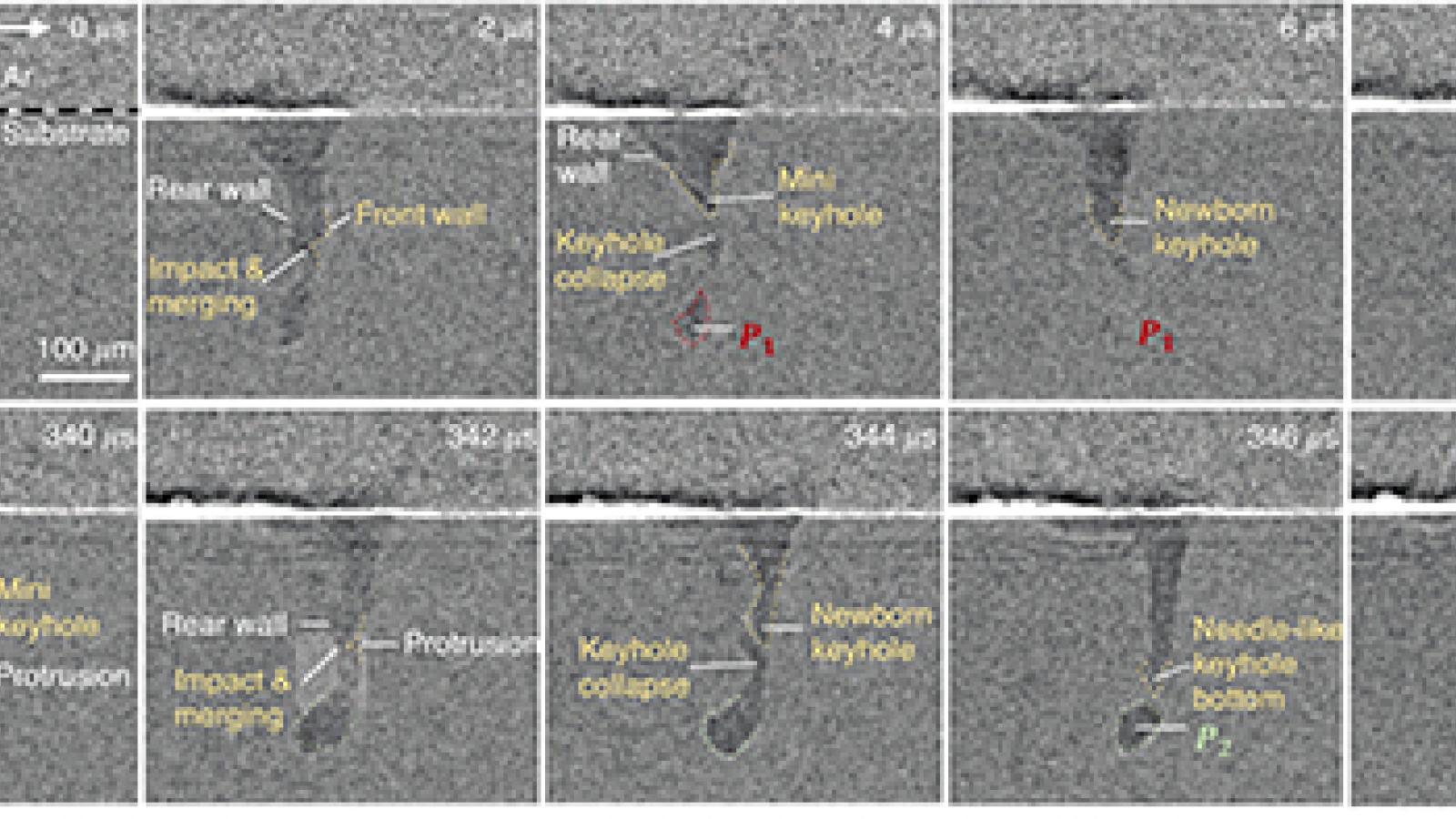

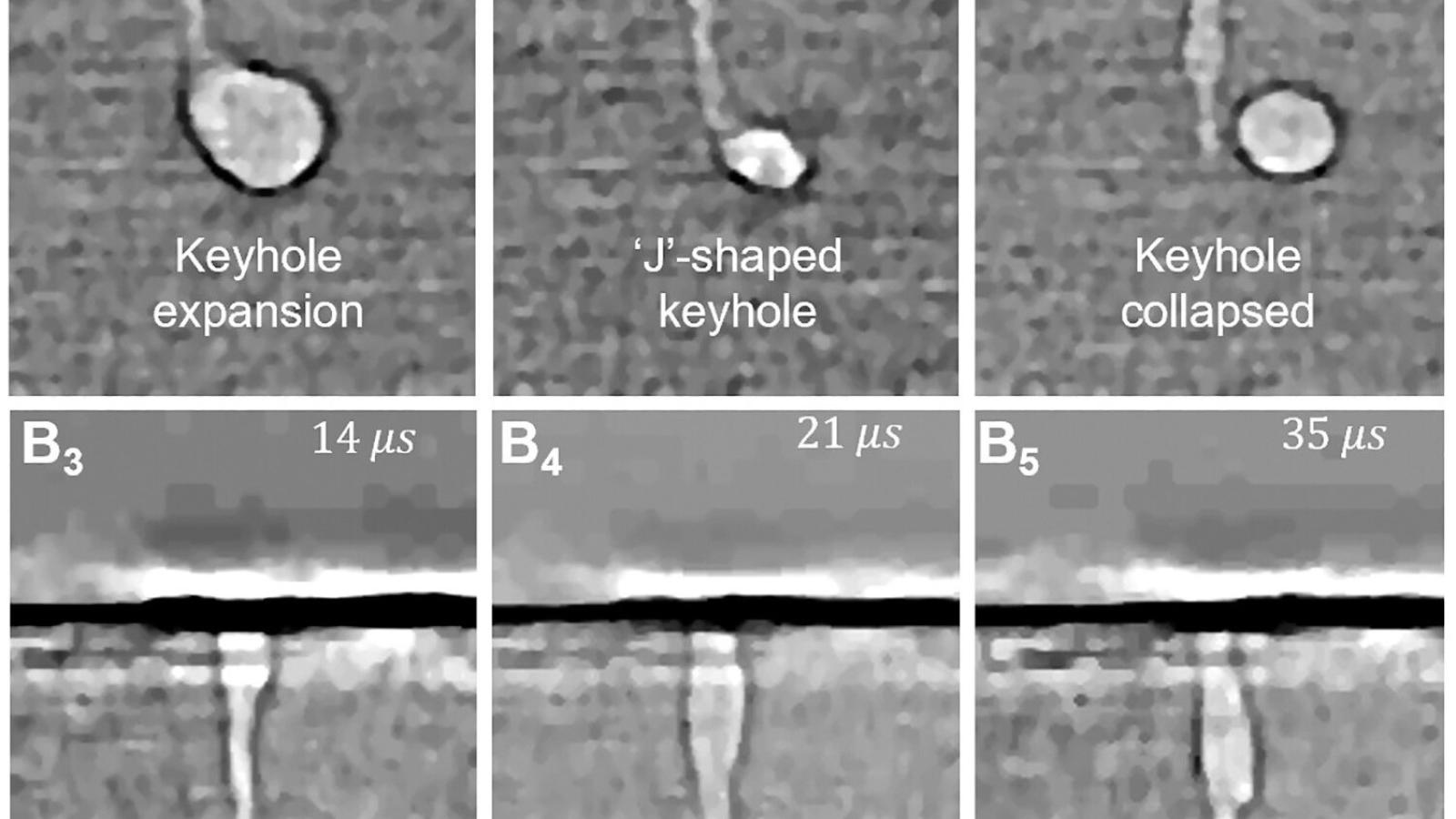

Ultrafast white-beam diffraction capability has been developed, serving as a complementary tool to the high-speed imaging technique. By integrating an intensifier with a multi-frame high-speed camera, high quality diffraction data can be recorded with MHz frame rates. The ultrafast diffraction instrument aims to provide users the unique capability to study the non-repeatable material behaviors by measuring the strain evolution and phase transformation occurring in a single dynamic event. It is particularly suitable for probing those ultrafast dynamics that cannot be captured by the conventional pump-probe techniques. An in-house developed software is distributed to users to aid the simulation and analysis of the white-beam diffraction patterns. For the high-speed x-ray imaging and diffraction program at 32-ID-B, the major improvements include: (1) Installation of in-vacuum high-heat-load fast shutter in the A-station, with full remote control of the settings and operation. This will save crucial space in the B station and allows for additional equipment safety interlocks when needed. (2) Installation of an exhaust system in the B-hutch, thus allowing new experiments requiring the use of toxic and flammable gases. (3) Development of a multi-frame, high-speed diffraction detection system based on a new intensified relay optics optimized for use with our Photron camera. This system can take unlimited number of frames, at up to 300 kHz, without (MCP) depletion issues. (4) Integration of an ultrafast framing camera (Shimadzu HPV-X2, in collaboration with a group from LANL) in our imaging and diffraction system, allowing for a frame rate up to the storage ring frequency of 6.5 MHz. (5) integration of a cooled compound refraction lenses (CRLs) system to focus the undulator beam: a step closer to getting a functional ultrafast SAXS system. (6) We started a new phase in the Additive Manufacturing setup improvements. We are integrating high speed IR and Visible light imaging as part of the scanner head itself. This will allow for unprecedented top view real time imaging of the sample. We also started a few collaborations to integrate standard calibration tools of the experimental conditions (laser beam profile and power, gas flow, ...). The in-situ laser additive manufacturing (AM) process replicator, shown in the Figure adjacent, has been developed at 32-ID-B,C for high-speed synchrotron X-ray imaging and diffraction studies (DOI: 10.1038/s41598-017-03761-2, DOI: 10.1107/S1600577518009554). Many highly time-transient processes and phenomena involved in metal AM have been quantitatively characterised with unprecedented spatial and temporal resolutions, and the mechanisms responsible for different types of defects in AM materials were identified. Whilst other groups around the world have built similar process replicators the instrument at 32-ID-B,C is unique in that it is routinely available for user experiments. As such this instrument has been highly successful resulting in the publication of 32 journal articles between 2017 and 2020. |

| 32-ID-C (XSD) Transmission X-ray Microscopy |

|

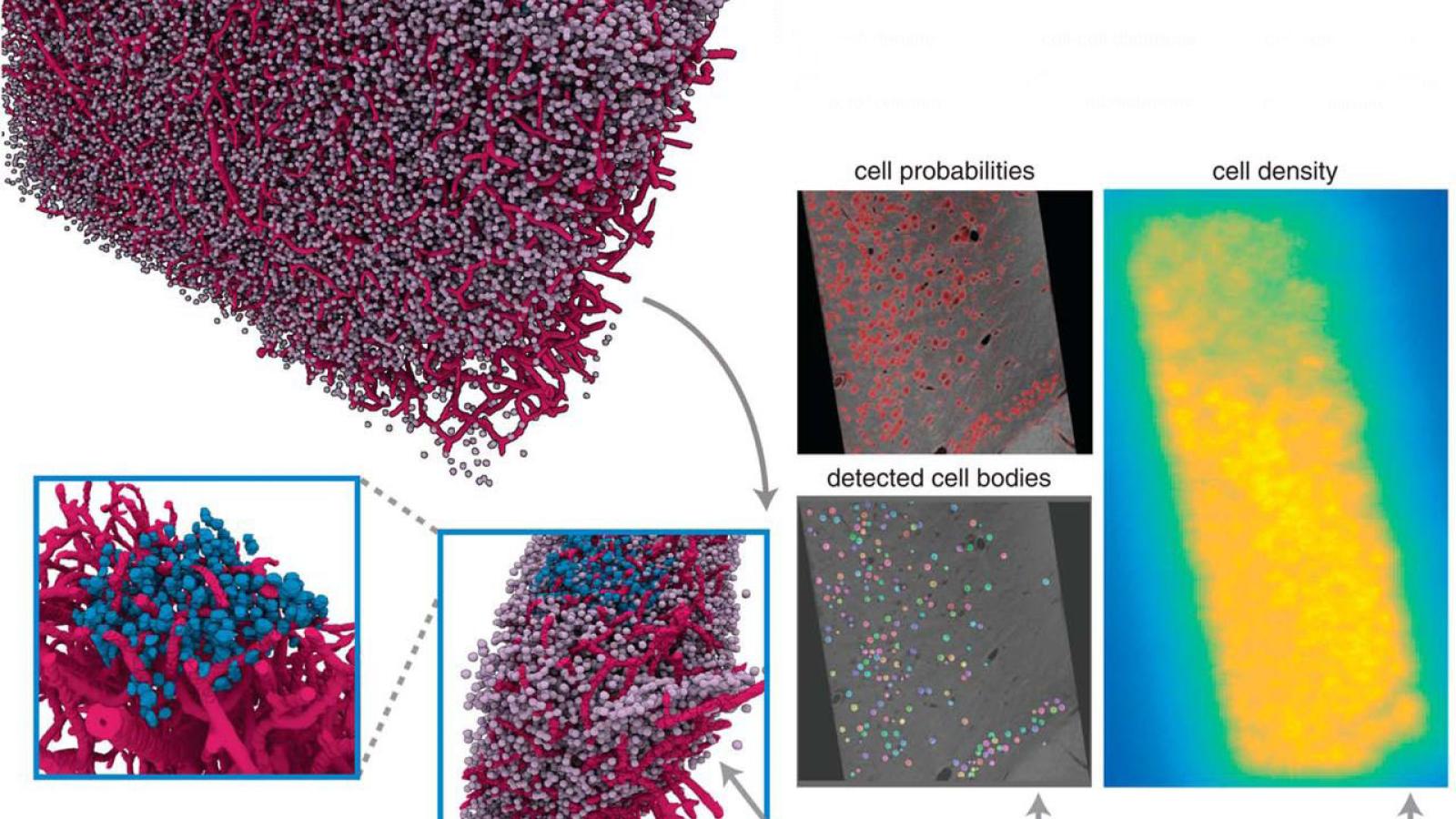

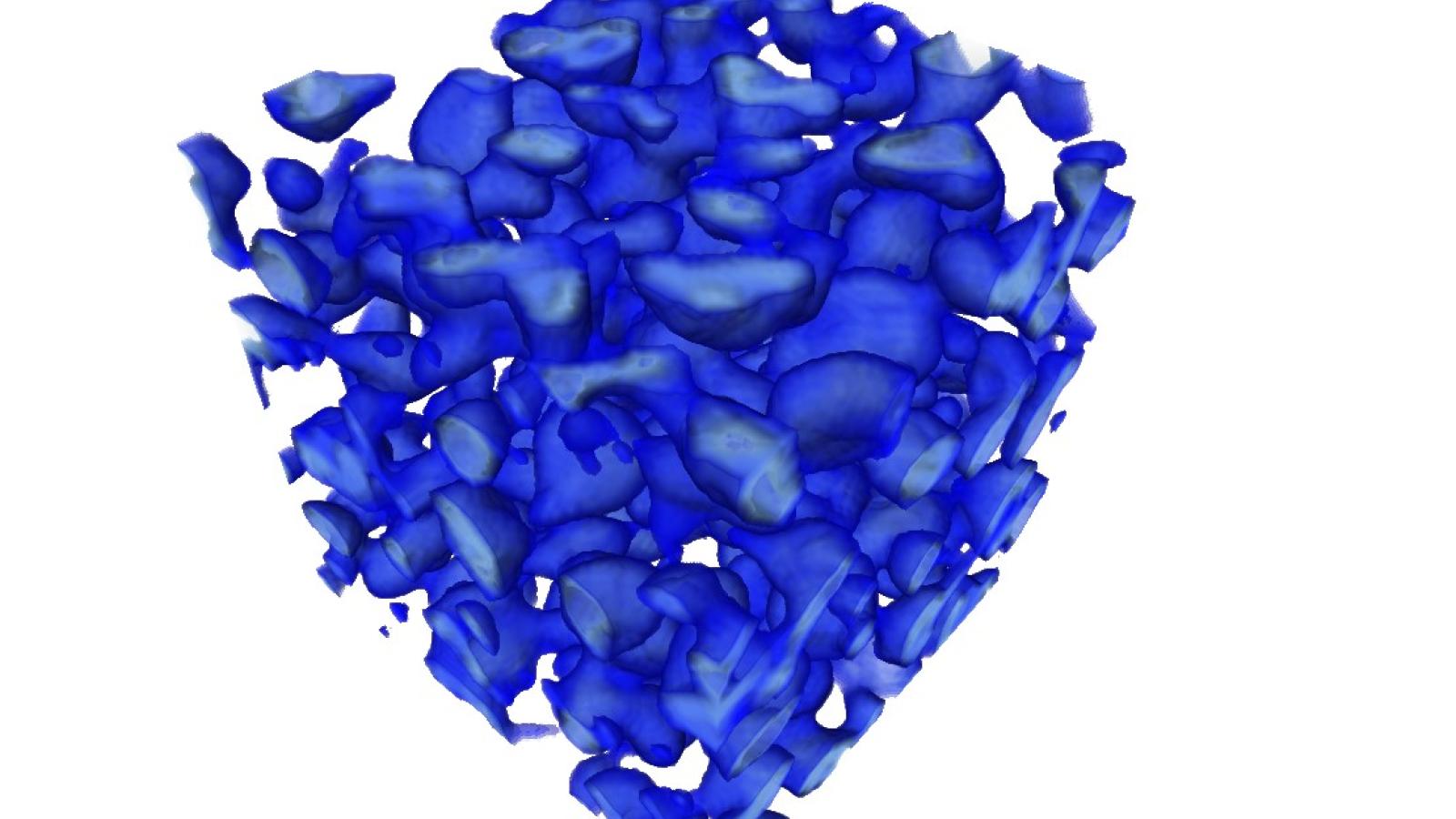

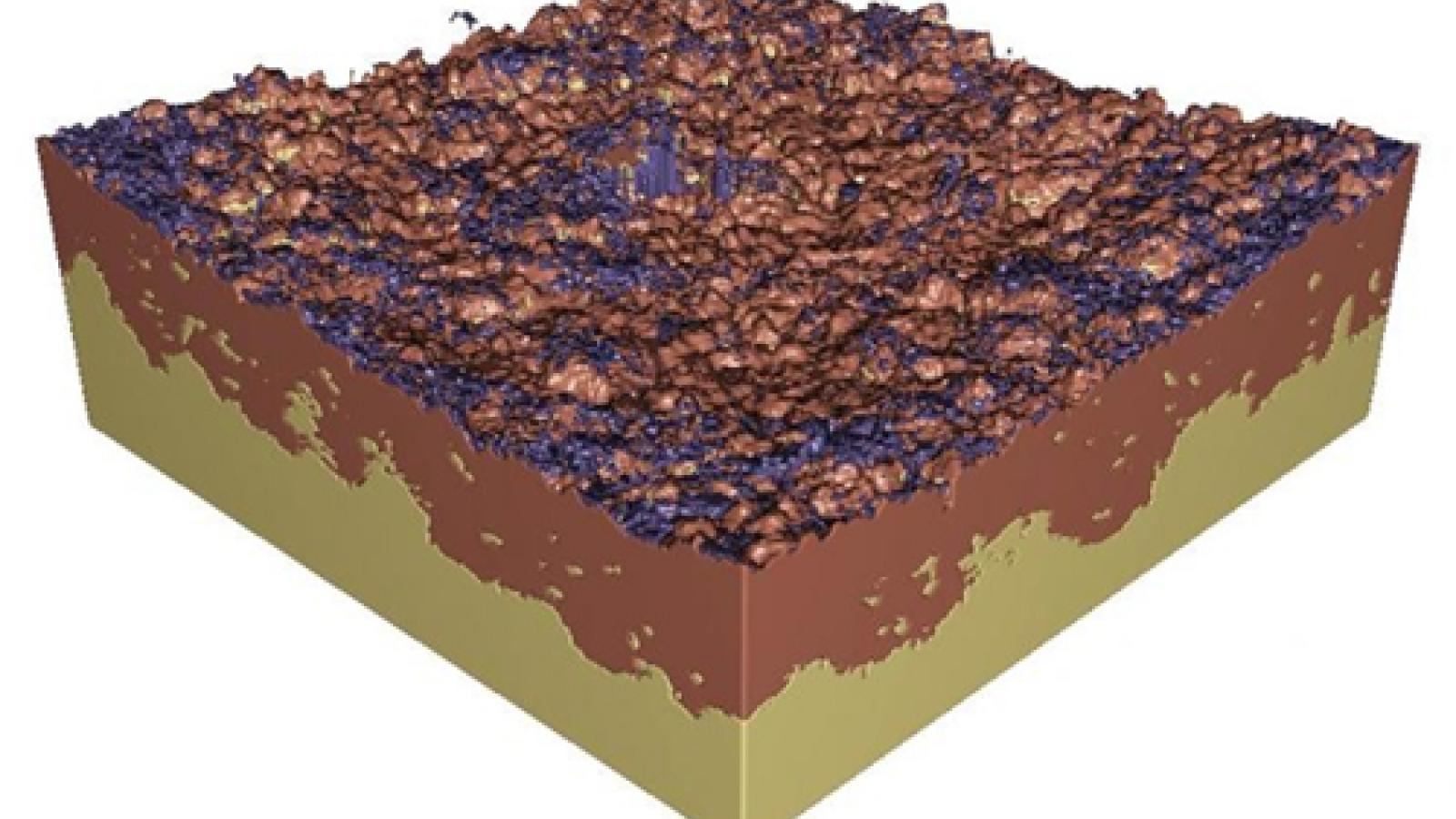

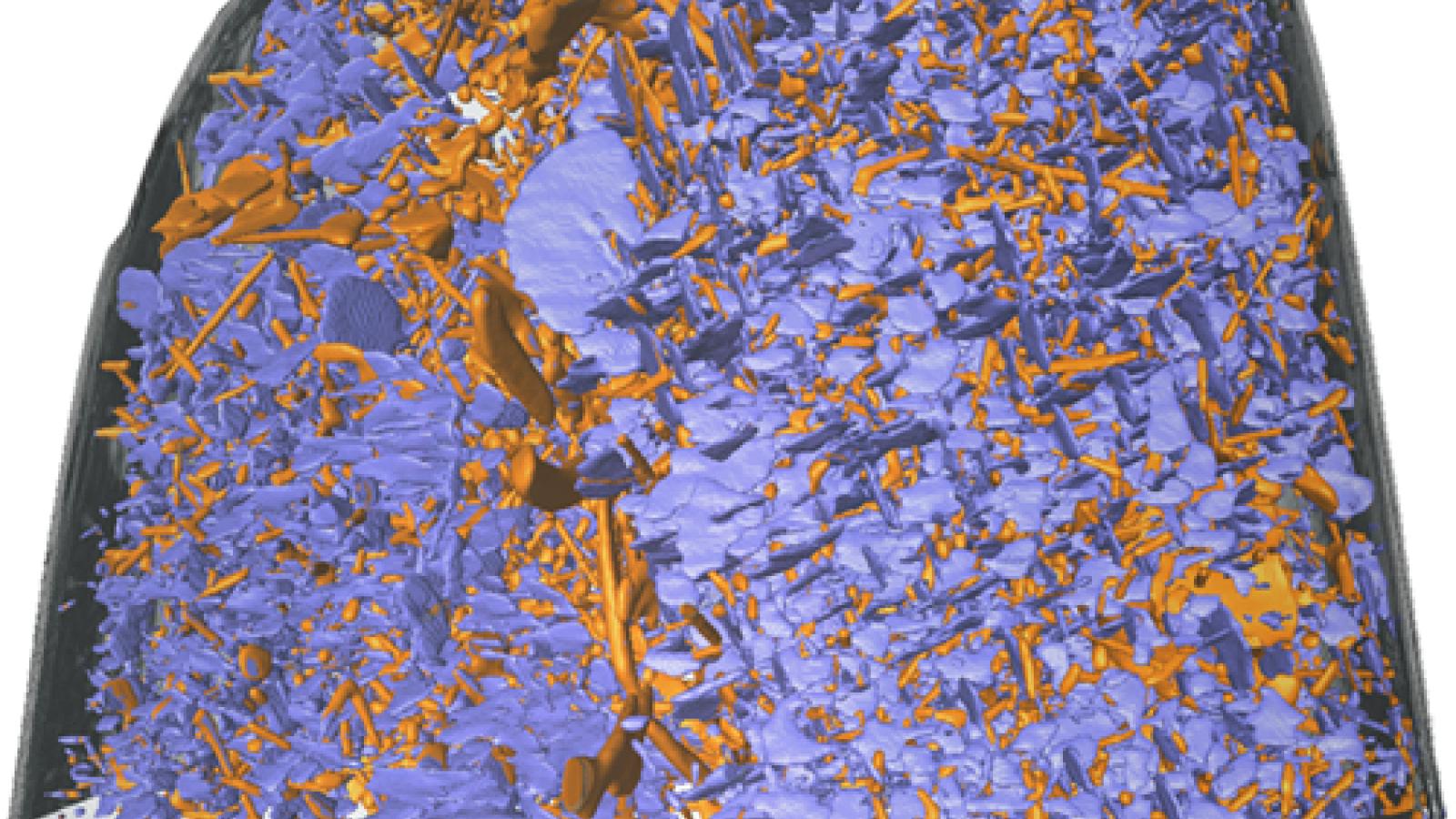

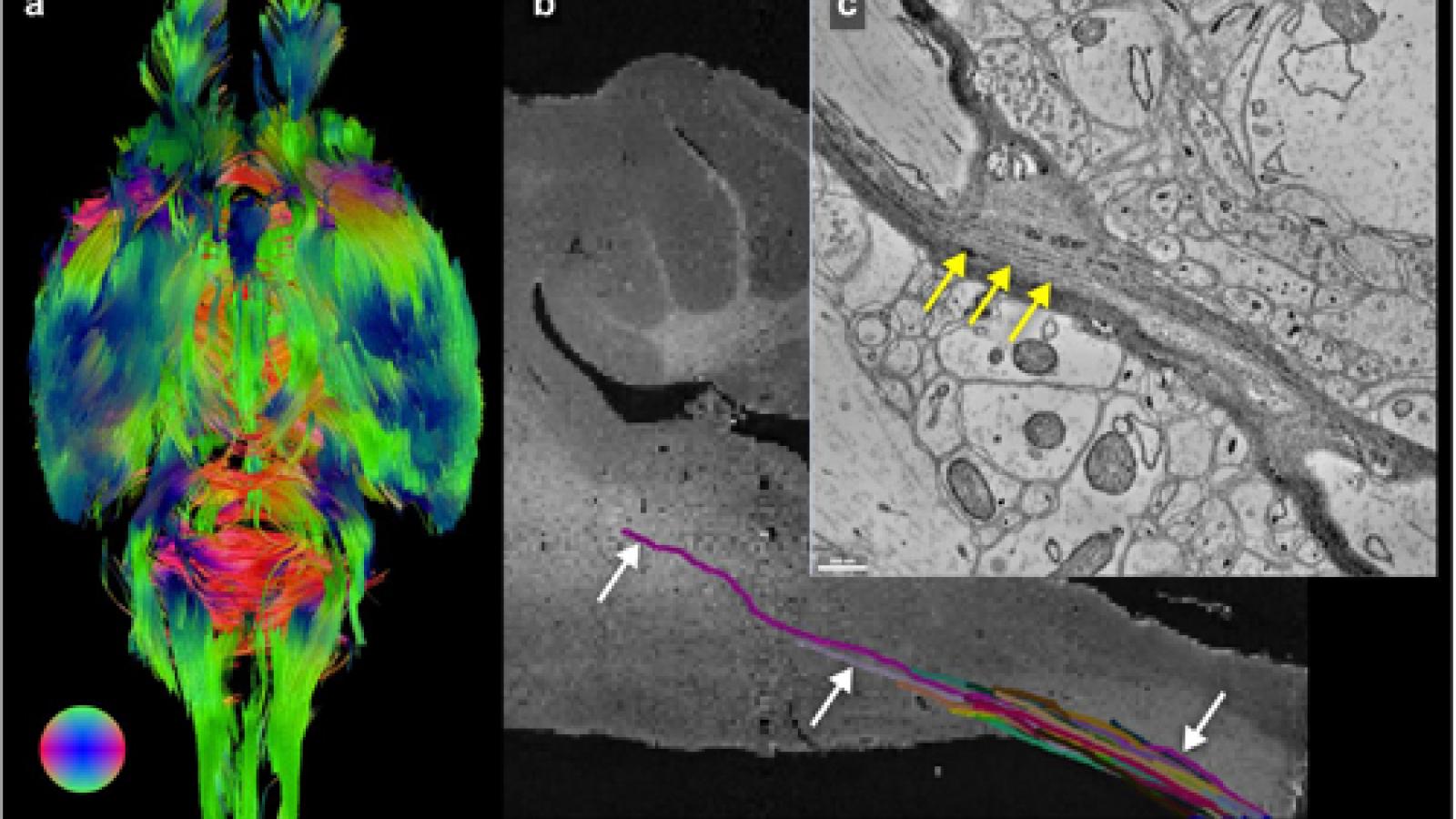

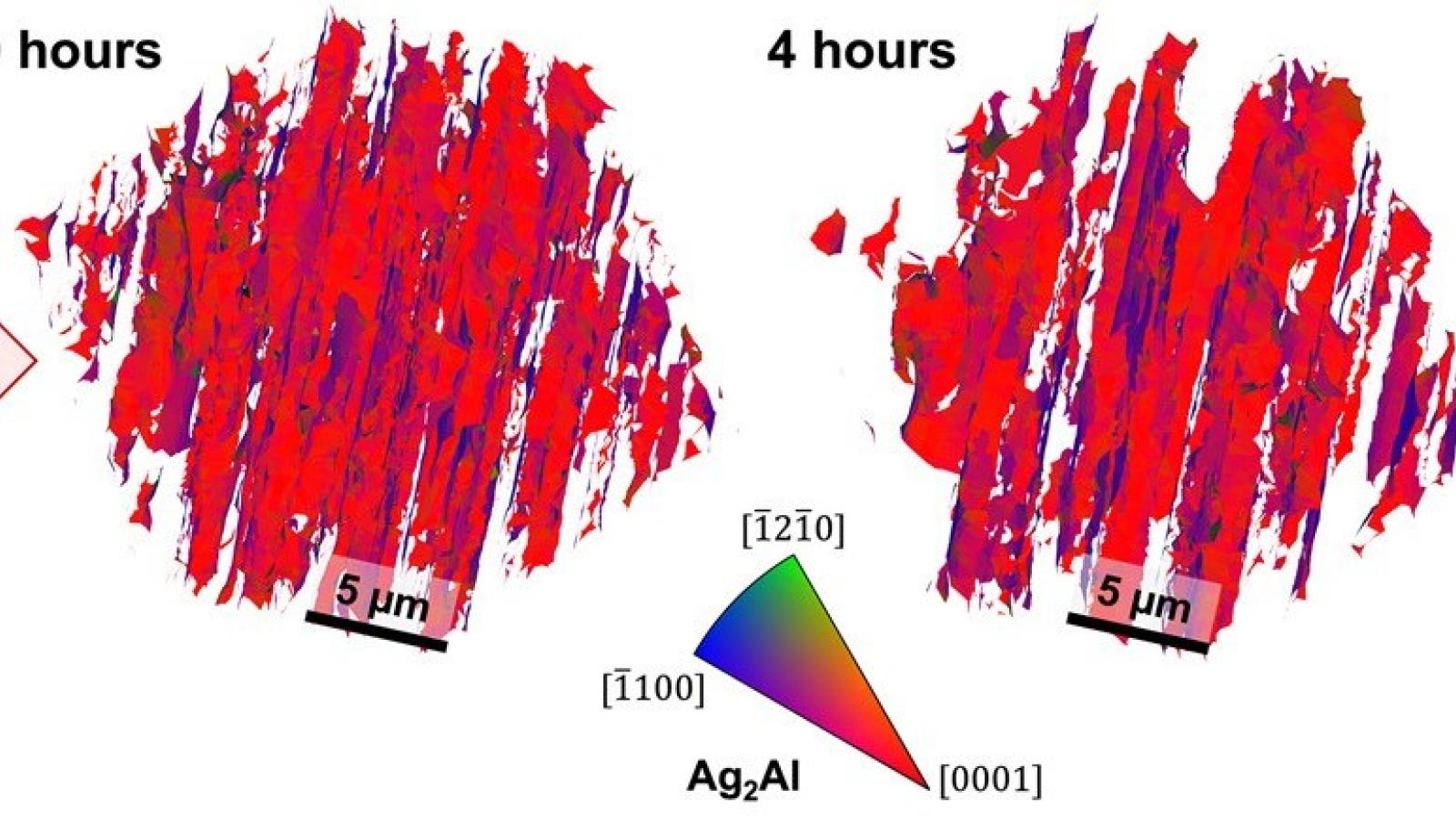

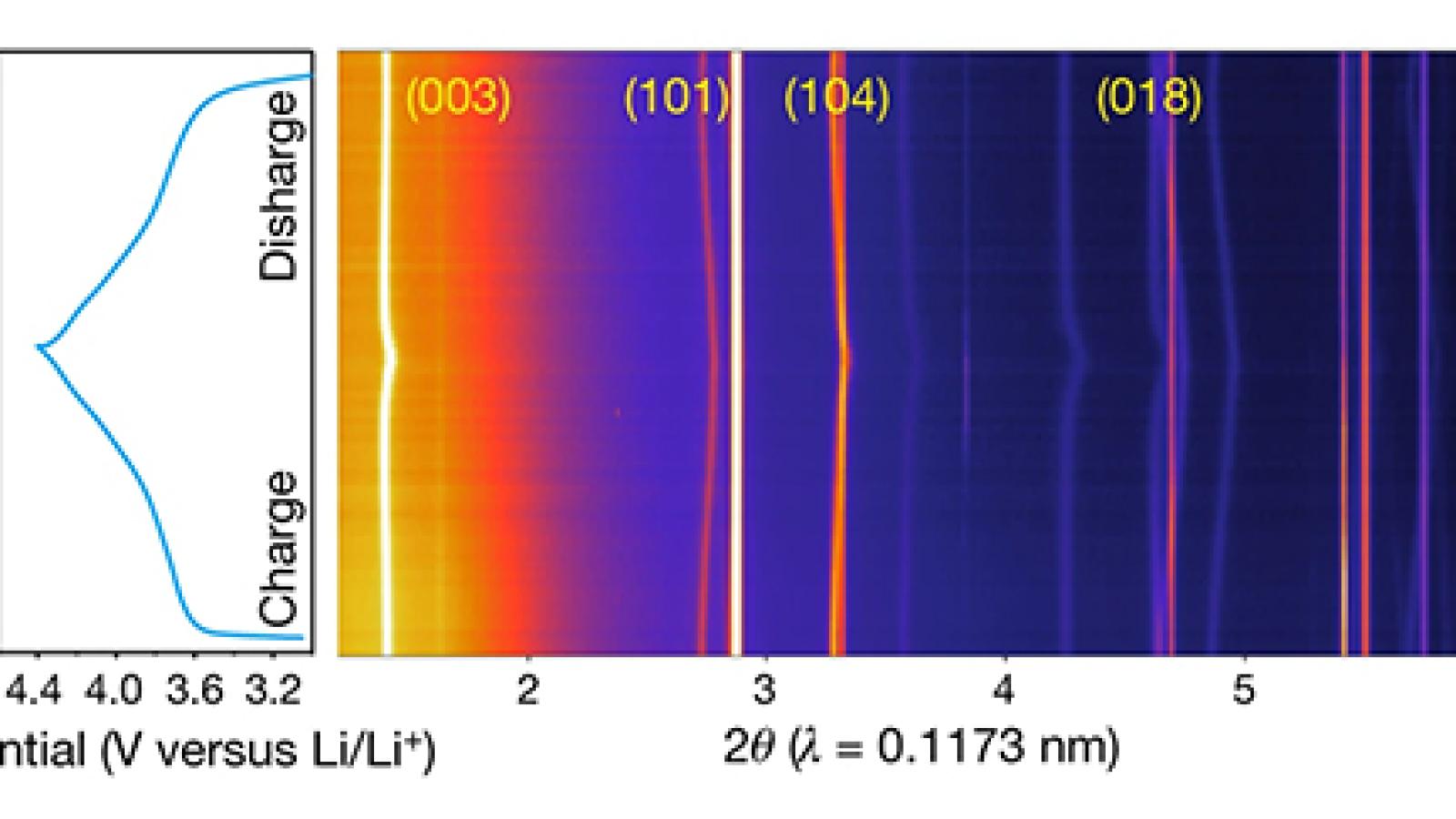

32-ID-C hosts an in-house designed and built full-field transmission x-ray microscope with sub‑10 nm spatial resolution for 2-D and 3-D imaging of several micrometer-thick materials (32-ID-C).For the transmission x-ray microscopy program at 32-ID-C, the major improvements include: 1) Various R&D activities (see 32-ID staff R&D section) improved the nano tomography instrument to achieve a sub-10 nm world record resolution (DOI: 10.1002/adma.202008653); 2) implemented a new standardized control system (TomoScan) that supports step & fly & interlaced scan and streaming data collection for tomography. 3) Added a granite air bearing based sample positioning system, a miniature programmable heat shielded furnace up to 1200 °C with in-situ scanning capability. Implemented a slip ring connectivity to allow continuous 360° rotation and passing signals to and from a rotating sample that allows in-situ imaging of battery cells during charge and discharge cycle. 4) Add thermal acoustic enclosure of the sample stack and optical elements. 5) Added remotely controlled He gas fill of the TXM optics enclosure that allows reduced He consumption. 6) Installed multiple web cameras and various software packages for remote operation. 7) Added a new user-friendly interface and additional functionality for controlling all TXM Optics. 8) Integrated ORS Dragonfly package for 3D volume rendering of reconstructed tomographic data. As such this instrument has been highly successful resulting in the publication of 67 journal articles in 2017-2020. |

| Data Analysis and Image Processing Software |

| Analysis of tomographic datasets is becoming progressively more challenging due to the increasing data acquisition rates that new technologies in X-ray sources and detectors enable. At the Imaging Group we developed a collaborative framework, tomoPy for the analysis of synchrotron tomographic data.TomoPy is a Python/C++ based framework, open-source, platform and data format independent, has multiprocessing capability and it is used routinely to process data from the 2-BM microCT and the 32-ID nanoCT systems. TomoPy includes direct Fourier and nonlinear reconstruction methods for incomplete tomographic dataset. These methods are used when is required to reduce dose and/or increase scanning speeds. All software tools supported by the Imaging group can be found on xray-imaging and tomography. |