Researchers have employed a fluid mechanics method to characterize the microstructure of tooth enamel, paving the way for potential advancements in the development of ceramic materials. This innovative technique enabled the team to generate digital representations of the arrangement of microscale rods in enamel, with the aim of using this information as a blueprint for creating advanced ceramic materials. The findings of this research were published in Acta Biomaterialia.

The resilience of teeth is crucial for mammals, as it directly impacts their ability to effectively consume food and sustain themselves. Enamel, the hard outer coating of teeth, plays a critical role in protecting the underlying tooth structure from mechanical damage and decay.

Material scientists and engineers have long been intrigued by enamel due to its remarkable strength and resistance to damage, which serves as motivation for the development of bioinspired materials with enhanced properties.

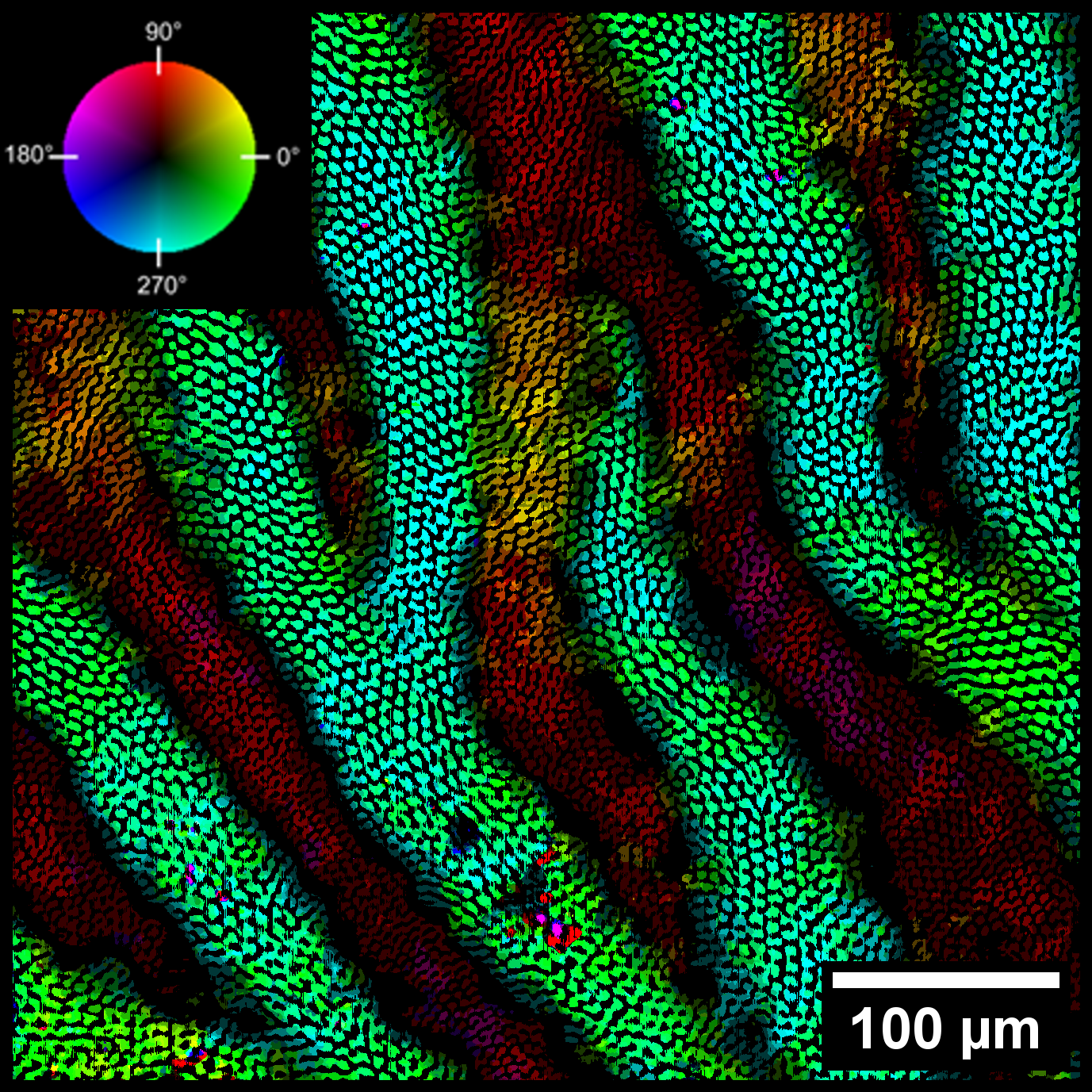

Enamel consists of cylindrical bundles of nanocrystals known as rods, which are approximately five microns in diameter. These rods are arranged in bands layered throughout the enamel, with adjacent bands having rods oriented at different angles to each other. This intricate three-dimensional microstructure serves to prevent cracks from propagating through the enamel.

When a crack forms, it travels along a rod until it encounters the next band of rods. The decussation pattern of the rods causes the crack to deflect and disperse in multiple directions, dissipating its energy and preventing it from progressing into the next band.

While the basic structure of enamel is understood, the orientation of rods through the thickness of enamel and across multiple bands has not been fully characterized. Previous imaging techniques have produced either two-dimensional scans or three-dimensional representations of individual enamel rods.

To overcome this limitation, a team of material scientists and engineers from the University of Washington, Seattle, and the U.S. Department of Energy’s (DOE) Idaho and Argonne national laboratories turned to a technique borrowed from fluid mechanics.

In optical flow velocimetry, tracer particles are introduced into fluids or air flows, and snapshots are taken to track their movement around objects. These snapshots are then compiled to create a three-dimensional representation of particle movement, revealing how the fluid flows around an object.

In this study, the researchers employed high-resolution computed tomography (CT) imaging to capture images of the enamel of an African lion's tooth. These CT scans produced a series of cross-sectional images through the thickness of the enamel. The researchers then employed software used for fluid flow analysis, repurposing it to interpret the cross-sections of enamel rods as moving particles.

By applying this technique, the software reconstructed the arrangement of rods in the enamel, creating a digital representation that accurately depicts the complex microstructures of the enamel, including the varying angles of the rods throughout large sections of material. The high-resolution CT images were obtained using high-energy synchrotron X-rays at Beamline 2-BM of the Advanced Photon Source (APS), an Office of Science user facility at Argonne.

Building upon the detailed information obtained about enamel structure and rod arrangement, the researchers have developed a mathematical model capable of reconstructing an idealized version of enamel's alternating rod structure for 3D printing.

Enamel primarily consists of hydroxyapatite, with the rods possessing one crystal structure of the mineral, while the matrix in which they are embedded has a different crystal arrangement. The researchers are using this information to 3D-print a ceramic material using alumina for the rods and zirconia for the matrix, with larger rods than those found in natural enamel.

Ceramic materials offer numerous advantages, including lightweight properties, exceptional strength, and high-temperature endurance. However, they are prone to brittleness and cracking under mechanical stress. The development of crack-resistant ceramics would represent a significant advancement, with potential applications in advanced structural components for hypersonic vehicles, nuclear reactors and next-generation gas turbines. – Michael Allen

See: Z. Guo1, D.P. Guillen1, J.R. Grimm2, C. Renteria2, C. Marsico1,2, V. Nikitin3, D. Arola1,4, “High-throughput automated characterization of enamel microstructure using synchrotron tomography and optical flow imaging,” Acta Biomaterialia (April 2024)

Author affiliations: 1Idaho National Laboratory; 2University of Washington; 3Argonne National Laboratory, 4School of Dentistry, University of Washington

Work was supported through Idaho National Laboratory's (INL's) Laboratory Directed Research & Development Program under Department of Energy (DOE) Idaho Operations Office Contract DE-AC07-05ID14517. C. Renteria acknowledges support, in part, by the NIH-NIDCR T90 DE021984 — Comprehensive Training in Inter-Disciplinary Oral Health Research Training Grant. C. Marsico acknowledges support from the Graduate Research Fellowship Program (GRFP) of the National Science Foundation and the Office of Science Graduate Student Research Program of the DOE. This research made use of the resources of the High Performance Computing Center at INL, which is supported by the Office of Nuclear Energy of the U.S. DOE and the Nuclear Science User Facilities under Contract No. DE-AC07-05ID14517. This research used resources of the APS, a U.S. DOE Office of Science User Facility operated for the DOE Office of Science by Argonne National Laboratory under Contract No. DE-AC02-06CH11357. Enamel specimens were provided by Jeff Bradley, Collection Manager at the Burke Museum.

The U.S. Department of Energy's APS at Argonne National Laboratory is one of the world’s most productive x-ray light source facilities. Each year, the APS provides high-brightness x-ray beams to a diverse community of more than 5,000 researchers in materials science, chemistry, condensed matter physics, the life and environmental sciences, and applied research. Researchers using the APS produce over 2,000 publications each year detailing impactful discoveries and solve more vital biological protein structures than users of any other x-ray light source research facility. APS x-rays are ideally suited for explorations of materials and biological structures; elemental distribution; chemical, magnetic, electronic states; and a wide range of technologically important engineering systems from batteries to fuel injector sprays, all of which are the foundations of our nation’s economic, technological, and physical well-being.

Argonne National Laboratory seeks solutions to pressing national problems in science and technology. The nation's first national laboratory, Argonne conducts leading-edge basic and applied scientific research in virtually every scientific discipline. Argonne researchers work closely with researchers from hundreds of companies, universities, and federal, state and municipal agencies to help them solve their specific problems, advance America's scientific leadership and prepare the nation for a better future. With employees from more than 60 nations, Argonne is managed by UChicago Argonne, LLC, for the U.S. DOE Office of Science.

The U.S. Department of Energy's Office of Science is the single largest supporter of basic research in the physical sciences in the United States and is working to address some of the most pressing challenges of our time. For more information, visit the Office of Science website.