Electron beam-powder bed fusion (EB-PBF) is an additive manufacturing technique that has grown rapidly in recent years due to its ability to manufacture high-performance metals and conductive ceramics. Preventing defects in three-dimensional (3-D)-printed parts created with EB-PBF requires understanding the process. Whereas in situ synchrotron x-ray imaging and diffraction have proven to be invaluable tools for understanding of laser-powder bed fusion (L-PBF), the characterization of the EB-PBF process has lagged what has been possible with laser-based additive manufacturing. Researchers have now created an open architecture EB-PBF system for in situ synchrotron x-ray monitoring and, using the U.S. Department of Energy’s Advanced Photon Source (APS), demonstrated that sub-surface properties of parts manufactured with this printing process can be readily visualized. The researchers’ open architecture system provides a powerful tool for studying in real time the dynamics and mechanisms of the EB-PBF process. Their results were published in the journal Additive Manufacturing Letters.

About a quarter century ago, scientists developed two techniques for metal additive manufacturing: L-PBF and EB-PBF. In a nutshell, these techniques begin with a base of metal powder on a substrate. An energy source, either an electron beam or a laser, then melts and fuses powder layers to construct parts from the bottom up.

EB-PBF, also known as electron beam melting, is useful for constructing complex metal parts, such as titanium aluminide turbine blades within jet engines, that are difficult or unachievable through conventional manufacturing routes. In addition, compared with L-PBF, EB-PBF offers lower residual stress; reduced support structures; a highly clean processing environment; higher production rate; and inertialess, fast, and accurate beam control.

Despite these many advantages, EB-PBF trails L-PBF in terms of overall metal additive manufacturing market share, with EB-PBF’s adoption rate under 10%. L-PBF has, literally and figuratively, left EB-PBF in the dust. One reason for this wide gulf in the adoption of these two technologies is a gap in the ability to visualize flaws in the finished products, which is key when manufacturing critical, high-end parts that need to withstand harsh environments. Failure due to defects hidden deep within parts is not an option. Yet because of a lack of understanding of the EB-PBF, hidden defects in parts made with the printing technique are likely to exist.

In situ synchrotron x-ray characterization of the transient dynamics in the L-PBF process has provided important insights on process instabilities and defect formation mechanisms. However, characterization of EB-PBF has been difficult due to the lack of an open architecture system for in situ observation of dynamics in the EB-PBF process, especially sub-surface phenomena.

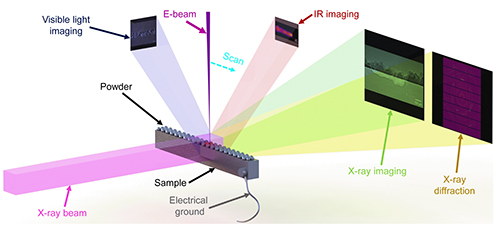

Now, researchers have created the world’s first system for concurrently using in situ synchrotron x-ray imaging and in situ x-ray diffraction, along with concurrent thermal and visible light imaging, to fully study several aspects of the EB-PBF printing process in real time (Fig. 1).

High-energy synchrotron x-ray imaging enables researchers to see, in unprecedented detail, how the material is behaving within the entire part—as it’s printing. A thermal camera allows the researchers to study how the temperature fluctuates during the process, while a visible light camera enables them to study the part’s evolving surface morphology.

In demonstration experiments, the researchers successfully obtained synchrotron x-ray images at the X-ray Science Division (XSD) Imaging Group’s 32-ID beamline at the APS during electron beam melting of Ti6Al4V and Al6061 samples. The powder morphology, vapor cavity, pores, melt pool and solidification front were sufficiently identified, proving the feasibility of using in situ high-speed x-ray imaging to reveal transient dynamics in EB-PBF process. X-ray diffraction images captured at the XSD Materials Physics & Engineering Group’s 1-ID beamline at the APS, taken during electron beam melting of the Ti6Al4V sample, demonstrated the feasibility of using in situ x-ray diffraction to reveal phase transformation dynamics in the EB-PBF process.

The research team overcame several technical challenges associated with studying the electron beam powder bed fusion process, including maintaining the high vacuum needed for the process, mitigating vibrations from the vacuum pump in their measurements, and manufacturing special viewports in the sample chamber so that the synchrotron’s x-rays could pass through them effectively.

The team designed the lightweight in situ characterization system to be an open-architecture system. Every component of the system can be exchanged, upgraded, and reconfigured according to the evolving research needs and it can be installed and aligned in under eight hours.

This integrated, real-time system represents a major step forward in researchers’ understanding of the fundamental mechanisms underlying the unique EB-PBF printing process, which previously had been limited to what could be seen on the surface of printed materials. ― Chris Palmer

See: Luis I. Escano1, Samuel J. Clark2, Andrew C. Chuang2, Jiandong Yuan1, Qilin Guo1, Minglei Qu1, William Dong1, Xinhang Zhang1, Junye Huang1, Kamel Fezzaa2, Peter Kenesei2, Brandon J. Walker3, Tao Sun4, Kevin W. Eliceiri3, and Lianyi Chen1*, “An electron beam melting system for in-situ synchrotron X-ray monitoring,” Add. Manuf. Lett. 3, 100094 (December 2022). DOI: 10.1016/j.addlet.2022.100094

Author affiliations: 1University of Wisconsin-Madison, 2Argonne National Laboratory, 3Morgridge Institute for Research, 4University of Virginia

Correspondence: * lianyi.chen@wisc.edu

This work is supported by the U.S. Department of Commerce (Award ID number: 70NANB21H039) and the University of Wisconsin- Madison Startup Fund (L.C.). This research used resources of the Advanced Photon Source, a U.S. Department of Energy (DOE) Office of Science user facility operated for the DOE Office of Science by Argonne National Laboratory under Contract No. DE-AC02-06CH11357.

The U.S. Department of Energy's APS at Argonne National Laboratory is one of the world’s most productive x-ray light source facilities. Each year, the APS provides high-brightness x-ray beams to a diverse community of more than 5,000 researchers in materials science, chemistry, condensed matter physics, the life and environmental sciences, and applied research. Researchers using the APS produce over 2,000 publications each year detailing impactful discoveries and solve more vital biological protein structures than users of any other x-ray light source research facility. APS x-rays are ideally suited for explorations of materials and biological structures; elemental distribution; chemical, magnetic, electronic states; and a wide range of technologically important engineering systems from batteries to fuel injector sprays, all of which are the foundations of our nation’s economic, technological, and physical well-being.

Argonne National Laboratory seeks solutions to pressing national problems in science and technology. The nation's first national laboratory, Argonne conducts leading-edge basic and applied scientific research in virtually every scientific discipline. Argonne researchers work closely with researchers from hundreds of companies, universities, and federal, state and municipal agencies to help them solve their specific problems, advance America's scientific leadership and prepare the nation for a better future. With employees from more than 60 nations, Argonne is managed by UChicago Argonne, LLC, for the U.S. DOE Office of Science.

The U.S. Department of Energy's Office of Science is the single largest supporter of basic research in the physical sciences in the United States and is working to address some of the most pressing challenges of our time. For more information, visit the Office of Science website.