The original University of Virginia School of Engineering and Applied Science news story can be read here.

A research team led by Tao Sun, associate professor of materials science and engineering at the University of Virginia, using data obtained via experiments at the U.S. Department of Energy’s Advanced Photon Source (APS) has made new discoveries that can expand additive manufacturing in aerospace and other industries that rely on high-performance metal parts. Their results were published in the journal Science.

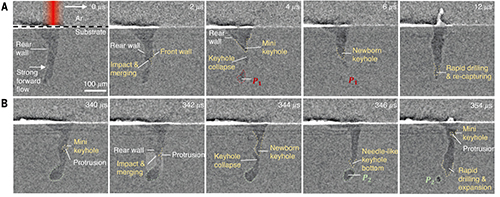

The results address the issue of detecting the formation of keyhole pores, one of the major defects in a common additive manufacturing technique called laser powder bed fusion, or LPBF.

Introduced in the 1990s, LPBF uses metal powder and lasers to three-dimensional (3-D) print metal parts. But porosity defects remain a challenge for fatigue-sensitive applications like aircraft wings. Some porosity is associated with deep and narrow vapor depressions which are the keyholes.

The formation and size of the keyhole is a function of laser power and scanning velocity, as well as the materials’ capacity to absorb laser energy. If the keyhole walls are stable, it enhances the surrounding material’s laser absorption and improves laser manufacturing efficiency. If, however, the walls are wobbly or collapse, the material solidifies around the keyhole, trapping the air pocket inside the newly formed layer of material. This makes the material more brittle and more likely to crack under environmental stress.

Sun and his team, including researchers from APS, Carnegie Mellon University (CMU), University of Wisconsin-Madison and DOE’s Kansas City National Security Campus, developed an approach to detect the exact moment when a keyhole pore forms during the printing process.

“By integrating operando synchrotron x-ray imaging, near-infrared imaging, and machine learning, our approach can capture the unique thermal signature associated with keyhole pore generation with sub-millisecond temporal resolution and 100% prediction rate,” Sun said. The operando high-speed synchrotron x-ray imaging experiments were performed at the APS X-ray Science Division (XSD) Imaging Group’s 32-ID-B x-ray beamline of the APS, a Department of Energy Office of Science user facility at Argonne National Laboratory.

In developing their real-time keyhole detection method, the researchers also advanced the way a state-of-the-art tool — operando synchrotron x-ray imaging — can be used. Utilizing machine learning, they additionally discovered two modes of keyhole oscillation.

“Our findings not only advance additive manufacturing research, but they can also practically serve to expand the commercial use of LPBF for metal parts manufacturing,” said Rollett, who is also the co-director of the NextManufacturing Center at CMU.

“Porosity in metal parts remains a major hurdle for wider adoption of LPBF technique in some industries. Keyhole porosity is the most challenging defect type when it comes to real-time detection using lab-scale sensors because it occurs stochastically beneath the surface,” Sun said. “Our approach provides a viable solution for high-fidelity, high-resolution detection of keyhole pore generation that can be readily applied in many additive manufacturing scenarios.”

“This work showcases how our unique laser powder bed fusion process replicator and million frames a second x-ray imaging enables researchers to test sensor concepts and transform how we control advanced manufacturing processes," said co-author Samuel Clark of the XSD Imaging Group.

See: Zhongshu Ren1, Lin Gao1, Samuel J. Clark2, Kamel Fezzaa2, Pavel Shevchenko2, Ann Choi3,4, Wes Everhart3, Anthony D. Rollett4, Lianyi Chen5, and Tao Sun1*, “Machine learning–aided real-time detection of keyhole pore generation in laser powder bed fusion,” Science 379, 89 (6 January 2023). DOI: 10.1126/science.add4667

Author affiliations: 1University of Virginia, 2Argonne National Laboratory, 3Kansas City National Security Campus Managed by Honeywell Federal Manufacturing and Technologies, 4Carnegie Mellon University, 5University of Wisconsin–Madison

Correspondence: * ts7qw@virginia.edu

This work was supported by the U.S. Department of Energy (DOE) Office of Science by Argonne National Laboratory under contract DEAC02-06CH11357 and Honeywell Federal Manufacturing & Technologies under contract DE-NA0002839 with the DOE. This research used resources of the Advanced Photon Source, a U.S. DOE Office of Science user facility operated for the DOE Office of Science by Argonne National Laboratory under Contract No. DE-AC02-06CH11357.

About UVA Engineering: As part of the top-ranked, comprehensive University of Virginia, UVA Engineering is one of the nation’s oldest and most respected engineering schools. Our mission is to make the world a better place by creating and disseminating knowledge and by preparing future engineering leaders. Outstanding students and faculty from around the world choose UVA Engineering because of our growing and internationally recognized education and research programs. UVA is the No. 1 public engineering school in the country for the percentage of women graduates, among schools with at least 75 degree earners; among the top engineering schools in the United States for the four-year graduation rate of undergraduate students; and among the top-growing public engineering schools in the country for the rate of Ph.D. enrollment growth. Our research program has grown by 95% since 2016. Learn more at engineering.virginia.edu.

The U.S. Department of Energy's APS at Argonne National Laboratory is one of the world’s most productive x-ray light source facilities. Each year, the APS provides high-brightness x-ray beams to a diverse community of more than 5,000 researchers in materials science, chemistry, condensed matter physics, the life and environmental sciences, and applied research. Researchers using the APS produce over 2,000 publications each year detailing impactful discoveries, and solve more vital biological protein structures than users of any other x-ray light source research facility. APS x-rays are ideally suited for explorations of materials and biological structures; elemental distribution; chemical, magnetic, electronic states; and a wide range of technologically important engineering systems from batteries to fuel injector sprays, all of which are the foundations of our nation’s economic, technological, and physical well-being.

Argonne National Laboratory seeks solutions to pressing national problems in science and technology. The nation's first national laboratory, Argonne conducts leading-edge basic and applied scientific research in virtually every scientific discipline. Argonne researchers work closely with researchers from hundreds of companies, universities, and federal, state and municipal agencies to help them solve their specific problems, advance America's scientific leadership and prepare the nation for a better future. With employees from more than 60 nations, Argonne is managed by UChicago Argonne, LLC, for the U.S. DOE Office of Science.

The U.S. Department of Energy's Office of Science is the single largest supporter of basic research in the physical sciences in the United States and is working to address some of the most pressing challenges of our time. For more information, visit the Office of Science website.