| The Metrology Laboratory role is to |

The metrology lab houses an array of non-contact profilers customized to evaluate optics and cover the wide range of surface spatial frequencies that are relevant to x-ray optics. These include a slope measuring system (i.e.; a long trace profiler), a laser figure interferometer; a microscope interferometer for surface roughness measurements with microstitching capability. These instruments are housed in a class 10,000 cleanroom located on the APS experiment hall floor, near sector 1. Work requests can be submitted by filling the Optics Group's work request form |

| Slope Measuring System (Long Trace Profiler - LTP) |

| Since Dec. 2012, the x-ray optics metrology laboratory is equipped with a new slope-measuring profiler (i.e., The long trace profiler -LTP) to measures slope and curvature of mirror surfaces along one dimension over a trace length up 1.5 m with the resolution of 50 nrad rms. The system was built around a high performance metrology gantry and motion system built by ALIO Inc. according to APS specifications. The system is housed in a custom made glass enclosure for environmental isolation. |

| Current features include |

|

| Roughness Microscope |

| The roughness interferometer is a model ADE-PhaseShift MicroXAM RTS. This system can operate in either a phase-shifting mode, using filtered light centered at 551 nm wavelength with 25 nm bandwidth or in a vertical scanning white light interferometric mode. The former is used for evaluating precisely figured very smooth surfaces while the latter is used for topography of rough surfaces. Five interchangeable objective lenses can be used to cover a wide range of magnifications with the field of view ranging in area from 240 µm × 240 µm up to 5mm × 5 mm. An integrated high-resolution closed-loop translation stage is used to scan the mirror's surface in both x and y directions to automatically acquire measurement maps at predetermined surface sites for roughness evaluation and for subaperture microstitching. |

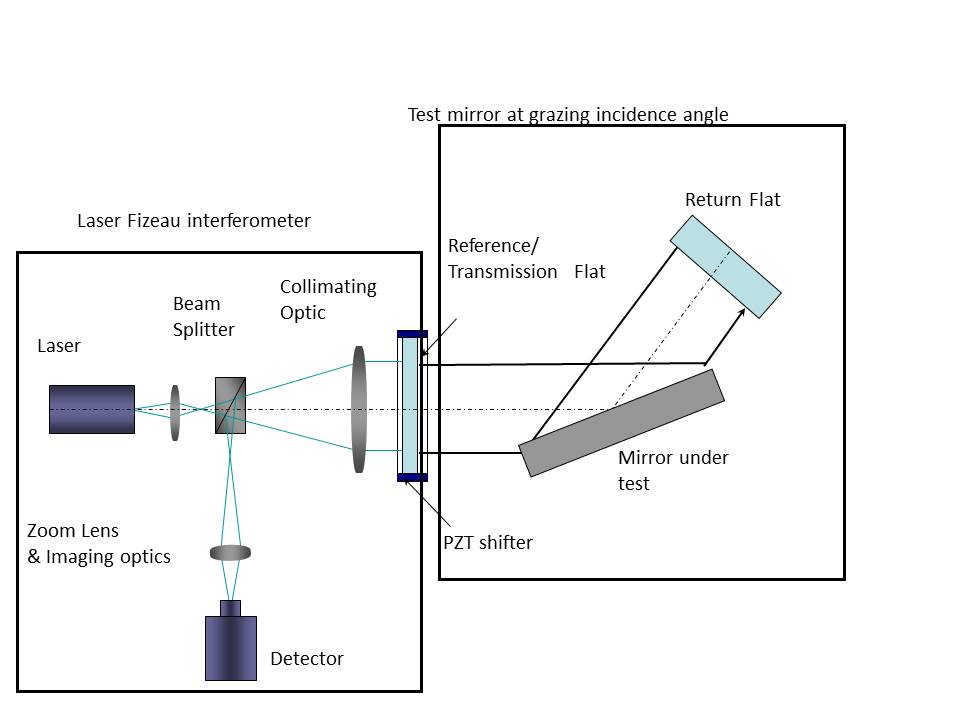

| Fizeau Interferometer |

| While optical metrology tools are adequate for day-to-day measurements and for rapid turnaround measurements to support the fabrication of K-B mirrors by profile coating, the true validation of an x-ray optics is best done at the working x-ray wavelength. To this end, an x-ray Talbot grating interferometer system is currently being implemented as standard for optics evaluation at 1-BM Optics and Detectors Testing beamline using operations funds. Typically, such work is performed as part of ongoing R&D programs or as part of collaborative efforts with the end user. |