If you ever built a complex model out of LEGOs, you know the value of assembling parts of that model in pieces before attaching them to the whole. That same strategy is being used to upgrade the electron storage ring at the heart of the Advanced Photon Source (APS), a U.S. Department of Energy Office of Science User Facility at Argonne National Laboratory.

The APS Upgrade project recently achieved a significant milestone with the first practice assembly of a module of powerful magnets. Ultimately 200 modules similar to this one will make up the new storage ring. A team of engineers and riggers used heavy cranes to lift magnets, some weighing thousands of pounds, and connect them to a cast iron girder and concrete plinth to form a module. This module will be disassembled and reassembled several times over the coming weeks to ensure that the process is as smooth as possible.

The new storage ring will include 1,321 powerful magnets, some the size of a dorm room fridge but weighing as much as an SUV. There are 15 different types of magnets included in the upgrade, all working together to steer and focus a beam of electrons as it circulates around the existing APS tunnel, which spans more than 2/3 of a mile in circumference. These electrons are used to create X-rays for more than 60 beamlines around the ring, and with the new magnets focusing those electrons into a tight beam, the X-rays will be up to 500 times brighter than those currently used at the APS.

APS Upgrade engineers and riggers (Mechanical Engineering Specialist Jeremy Nudell, Drivers/Riggers Ryan Roberts and Brian McFadden, Principal Mechanical Engineer Ken Volin and Principal Mechanical Engineering Specialist Ralph Bechtold, L-R) stand by the first assembled module of magnets that will comprise the new storage ring for the Advanced Photon Source. There will be 200 modules assembled and transported to the APS during the upgrade project. Image by JJ Starr/Argonne National Laboratory

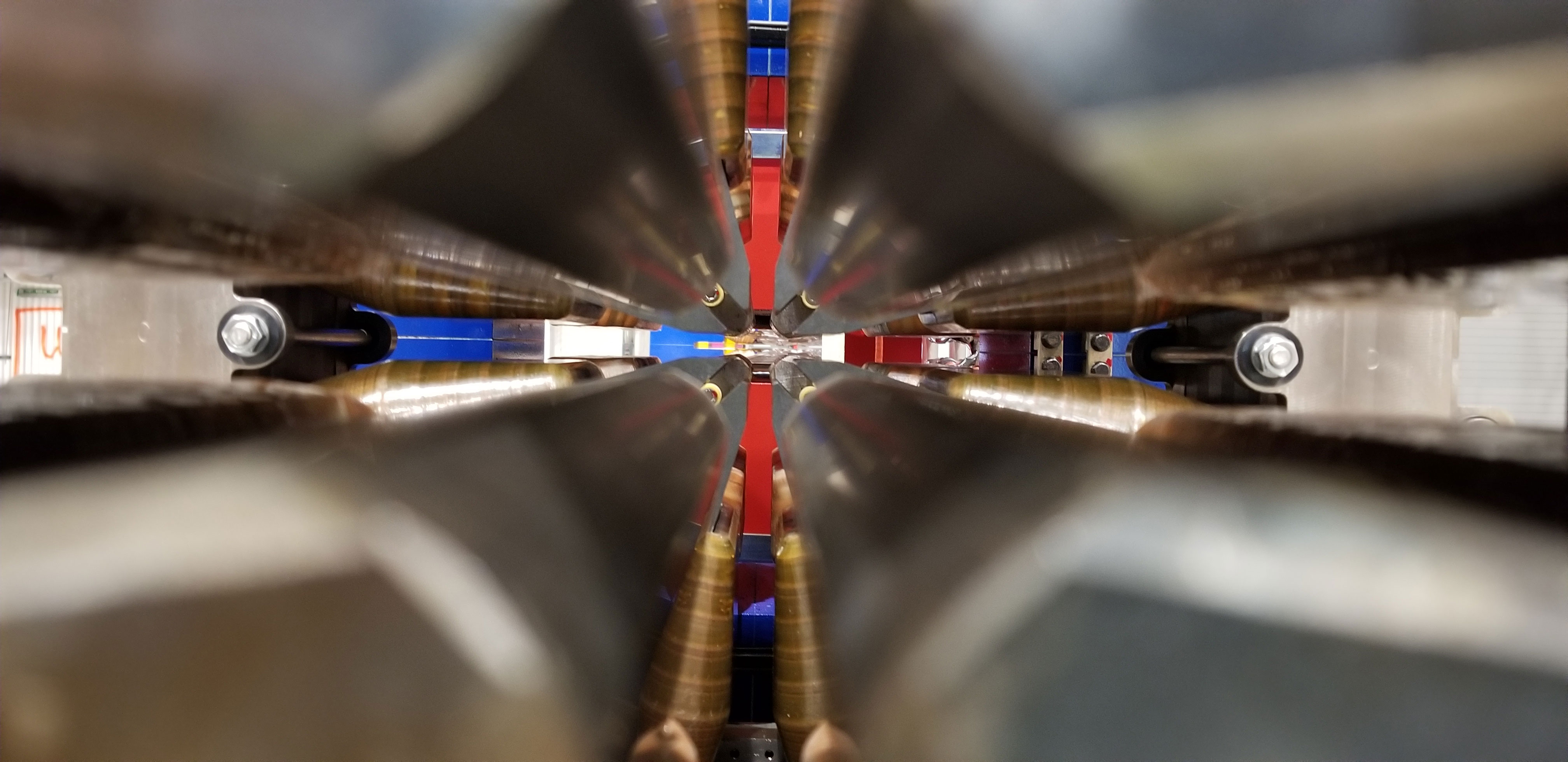

This image shows the path the electron beam will take through the center of the focusing and bending magnets as it circulates around the upgraded APS storage ring. Each of the 1,321 magnets that will make up the storage ring must be aligned with its neighbors to within half the width of a human hair. Image by Ken Volin/Argonne National Laboratory

Driver/Rigger Brian McFadden uses a crane to lift a 660-pound quadrupole magnet, the final magnet to complete the first practice assembly for the upgrade of the Advanced Photon Source. Image by JJ Starr/Argonne National Laboratory

Driver/Rigger Brian McFadden maneuvers a 660-pound quadrupole magnet towards a girder, where it will complete the first practice module for the upgrade of the Advanced Photon Source. 1,321 magnets of various types will be assembled into modules for the upgrade of the storage ring. Image by JJ Starr/Argonne National Laboratory

Each of those magnets, once it arrives at Argonne, must be tested to ensure that its magnetic field meets the stringent requirements for the upgrade. Then the magnets will be mounted onto plinth assemblies, and each magnet must precisely align with its neighbors. The allowable misalignment is 30 microns, about half the width of a human hair.

“Each one of these large magnet assemblies forms a module and there are five modules to a sector,” explained Jeremy Nudell, the mechanical engineering specialist in charge of storage ring pre-installation assembly. “There are 40 sectors around the ring, and we will assemble each sector one module at a time.”

Nudell noted that this practice assembly doesn’t include the vacuum system, which will surround the electron beam with an airtight pipe, keeping the beam from dissipating due to interaction with the atmosphere. Once the vacuum system has been manufactured, the upgrade team will add it to the assembly process.

“Over the next six months we will finalize our procedure to mount and align these magnets, and as the vacuum systems arrive, we will finalize those procedures as well,” Nudell said.

Driver/Rigger Ryan Roberts operates a heavy crane while Driver/Rigger Brian McFadden and Principal Mechanical Engineering Specialist Ralph Bechtold gently maneuver a 660-pound quadrupole magnet into place on the first module assembled for the upgrade of the Advanced Photon Source’s storage ring. Image by JJ Starr/Argonne National Laboratory

Driver/Rigger Brian McFadden and Principal Mechanical Engineering Specialist Ralph Bechtold carefully maneuver a 660-pound quadrupole magnet onto a cast iron girder, completing the first practice assembly which will form the first of 200 magnet modules that will be used in the upgrade of the Advanced Photon Source’s storage ring. Image by JJ Starr/Argonne National Laboratory

Driver/Rigger Ryan Roberts disassembles connections on a quadrupole magnet that has been moved into place, completing the first practice assembly of the first magnet module that will be used in the upgrade of the Advanced Photon Source’s storage ring. The alignment of each of these magnets with its neighbors must be checked after assembly, to within half the width of a human hair. Image by JJ Starr/Argonne National Laboratory

The completed first module of magnets for the upgrade of the Advanced Photon Source’s storage ring. This module is a Doublet-L-bend Multiplet (DLM) module, and contains 11 individual magnets which focus and steer the electron beam. It sits on a transporter system that will be used to slowly move the modules from the loading dock into the storage ring tunnel by remote control. Image by JJ Starr/Argonne National Laboratory