Additive manufacturing, otherwise known as 3D printing, has become an essential tool of manufacturing on both the small and large scales, with a wide range of different techniques available depending on the particular requirements. The most prominent method for the creation of large-scale metallic parts is directed energy deposition (DED), in which lasers or other energy sources are used to melt a powder stream or wire feedstock to deposit the material layer by layer on the build platform.

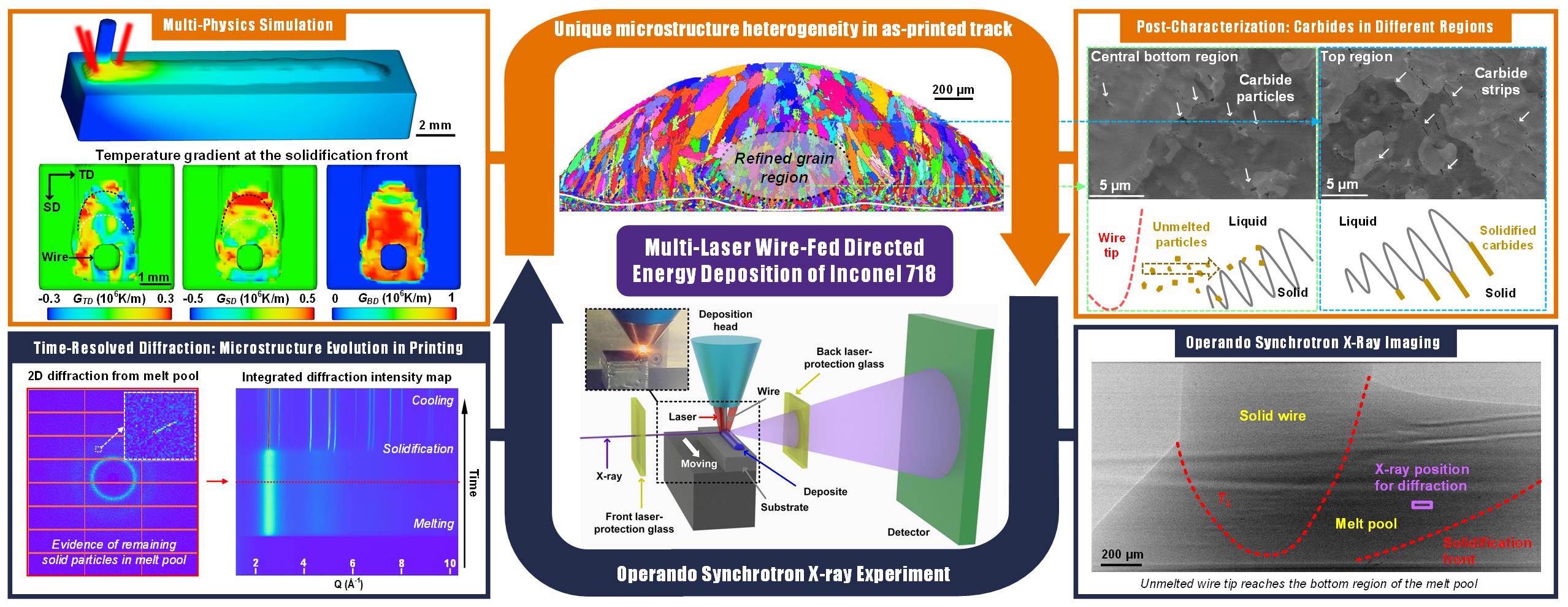

Because the specifics of the DED setup can have major effects on the quality of the finished product, however, an in-depth understanding of what's happening inside the melt pool during the deposition process is essential. A team from the University of Virginia, Northwestern University, and Argonne National Laboratory used operando synchrotron hard X-ray techniques and multi-physics modeling to penetrate the process of a little-studied wire-laser DED technique. The work appeared in International Journal of Machine Tools and Manufacture.

The wire-laser variety of DED manufacturing has been used for many years, generally with the wire being fed into the printhead at an angle. However, because it was found that this configuration can result in a directional dependence that causes anisotropic deposition, a different configuration was developed in which the feedstock wire is fed centrally in a coaxial setup with lasers focused on the wire tip, which provides a more even distribution of laser energy and thus greater homogeneity in the build microstructure. This, along with a faster deposition rate, lower costs, and greater efficiency, has increased the popularity of the coaxial wire-laser method in recent years.

Still, there are some issues, mainly dependent on the volumetric energy density (VED) used. Too high a VED can cause beading and dripping at the wire tip, while too low a VED can result in insufficient melting, even forming wire stubbing. Although the general consensus among DED users is that the latter scenario is more manageable than incomplete wire melting, either can create defects in the final product. Efforts to better understand the wire-laser DED process through optical imaging, sensing and simulation have been hampered by their inherent limitations and provide only an incomplete picture.

To overcome those limitations in the present work, the researchers studied the wire-laser DED process of the Inconel 718 superalloy for the first time under operando hard X-ray synchrotron experiments at the 1-ID-E beamline of the Advanced Photon Source, a U.S. Department of Energy (DOE) Office of Science user facility at DOE’s Argonne National Laboratory. This work innovatively combined full-field X-ray imaging and time-resolved X-ray diffraction to probe the printing process with a high spatiotemporal resolution. The X-ray imaging and diffraction observations were supplemented with multiphysics simulations using the Flow-3D software package.

In the first condition studied, which was designed to fall into a window between wire stubbing and complete melting, the feed wire was seen to be only partially melted upon entering the melt pool and reached the bottom but melted more completely as heating continued. After the end of the printing process, rapid cooling and solidification is seen, with a phase evolution proceeding from liquid to gamma, along with the generation of Laves, MC-carbide and delta phases.

However, the operando X-ray observations show that, under such a printing condition, the solidification process is affected by some residual solid particles, mostly MC-carbides in the bottom of the melt pool. This produced a unique heterogeneity in the finished printed product, with small, refined grains surrounded by larger columnar grains. The investigators attribute this to incomplete melting of wire feedstock within the melt pool. In the other two printing conditions studied using higher VEDs, the feedstock wire is fully melted at the bottom of the melt pool, which is also confirmed on the multiphysics simulation studies.

The researchers note that even with the wire melted insufficiently with the lower VED condition, the printing process was still successful without any major build defects, indicating the presence of a narrow but unique window of printing parameters. This raises the intriguing possibility of precisely tailoring the microstructure and properties of materials made by wire-laser DED techniques by controlling the melting of the feedstock wire. The deeper understanding of the complexities of the wire-laser DED process provided by this present work can lay the foundation for future enhancements and refinements of this indispensable and versatile additive manufacturing technique. – Mark Wolverton

See: L. Gao1, A.C. Chuang2, P. Kenesei2, Z. Ren1,3, L. Balderson1, T. Sun1,3, “An operando synchrotron study on the effect of wire melting state on solidification microstructures of Inconel 718 in wire-laser directed energy deposition,” International Journal of Machine Tools and Manufacture 194 (January 2024)

Author affiliations: 1University of Virginia; 2Argonne National Laboratory; 3Northwestern University

The authors would like to thank Alex Deriy and Ali Mashayekhi at the Advanced Photon Source of Argonne National Laboratory for their assistance in the beamline experiment. This research used resources of the Advanced Photon Source, a U.S. Department of Energy (DOE) Office of Science user facility operated for the DOE Office of Science by Argonne National Laboratory under Contract No. DE-AC02-06CH11357.

The U.S. Department of Energy's APS at Argonne National Laboratory is one of the world’s most productive x-ray light source facilities. Each year, the APS provides high-brightness x-ray beams to a diverse community of more than 5,000 researchers in materials science, chemistry, condensed matter physics, the life and environmental sciences, and applied research. Researchers using the APS produce over 2,000 publications each year detailing impactful discoveries and solve more vital biological protein structures than users of any other x-ray light source research facility. APS x-rays are ideally suited for explorations of materials and biological structures; elemental distribution; chemical, magnetic, electronic states; and a wide range of technologically important engineering systems from batteries to fuel injector sprays, all of which are the foundations of our nation’s economic, technological, and physical well-being.

Argonne National Laboratory seeks solutions to pressing national problems in science and technology. The nation's first national laboratory, Argonne conducts leading-edge basic and applied scientific research in virtually every scientific discipline. Argonne researchers work closely with researchers from hundreds of companies, universities, and federal, state and municipal agencies to help them solve their specific problems, advance America's scientific leadership and prepare the nation for a better future. With employees from more than 60 nations, Argonne is managed by UChicago Argonne, LLC, for the U.S. DOE Office of Science.

The U.S. Department of Energy's Office of Science is the single largest supporter of basic research in the physical sciences in the United States and is working to address some of the most pressing challenges of our time. For more information, visit the Office of Science website.