Three-dimensional carbon superstructures are useful in a wide variety of applications, including batteries, catalysis and gas storage. Now scientists have come up with an easy and inexpensive way to make one- and two-dimensional versions of the same material. The research team used the Advanced Photon Source (APS), a U.S. Department of Energy (DOE) Office of Science user facility at DOE’s Argonne National Laboratory, to show that they can form a wide variety of the structures by tuning the growth conditions.

Polyacrylonitrile (PAN) is the polymer carbon used to synthesize these superstructures. In fact, PAN is the basis for more than 90% of global carbon fiber production. The resulting materials have high surface area, tunable pore sizes and structures, surface properties that can be adjusted, high chemical stability and good thermal and electrical conductivity. Various methods such as templating can create PAN superstructures, but the synthesis processes can be complex and costly.

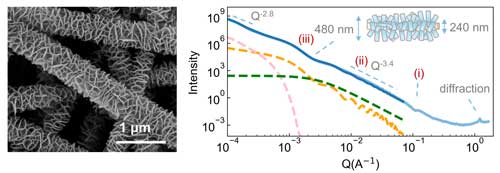

Researchers found they could control the self-assembly of PAN nanosheets into 1D nanofibers and 2D thin films. The usual synthesis method causes the PAN to form round particles that resemble a flower. Instead, the team prepared a solution of acrylonitrile and azobisisobutyronitrile in acetone. They placed a substrate that had been treated with oxygen plasma, such as a silicon wafer, into the solution, then heated it to 70°C. A series of nanosheets formed on top of the wafer, growing roughly perpendicular to the surface.

To grow 1D nanofibers, the scientists used a similar process, but instead of a flat wafer as the substrate they used an existing nanofiber. Researchers took nanofiber that had been created through the electrospinning process, heated it to 250°C to stabilize it, and placed it in the solution. PAN nanosheets grew on the surface of the bare nanofibers, forming new nanofibers with nanostructures determined by the growth conditions. The nanostructured fibers could be carbonized to form porous carbon nanofibers, and when they intersected they formed free-standing cloths. Such material has great potential in applications such as membranes for purification and separation.

The use of different solvents in the synthesis process produced a range of variations in the resulting PAN nanosheets. For instance, using tetrahydrofuran (THF) caused the orientation of the nanosheets to be more perpendicular, and the flower-like particles were grouped less densely. If, instead, pyradine were used as the solvent, the particles became denser and the nanosheets formed smaller with a more random orientation. Particles polymerized in hexanes formed clumps of nanospheres without nanosheets. Using methanol produced leaf-like nanosheets with a more random orientation than THF.

Additionally, altering conditions like the concentration of the solution or the shape of the substrate also changed the final structure. Coating a silicon wafer covered with PAN nanosheets with gold produced a superhydrophobic surface with a contact angle close to 180°.

To see what their nanomaterials looked like, the team performed ultra-small-angle X-ray scattering studies at beamline 20-ID-B at the APS, a technique which will be available at beamline 12-ID-C as the

upgraded APS resumes its operation this summer. That allowed them to see the structure at a scale from micrometers down to nanometers and make quantitative measurements of that structure. It also allowed them to see inside the materials and to identify structures such as microvoids in the fibers. The researchers said the APS is the only place in the US where they could perform this sort of measurement.

They also performed grazing-incidence wide-angle X-ray scattering at beamline 7.3.3 of the Advanced Light Source at Lawrence Berkeley National Laboratory. Those studies allowed them to determine that the nanosheets first formed parallel to the substrates before new layers become more perpendicular. – Neil Savage

--------------------------------------------------------------------------------------------------------------------------------------------

See: H. Gong1, D.U. Patino1, J. Ilavsky2, I. Kuzmenko2, A.E. Pena-Alcantara1, C. Zhu3, A.H. Coffey3, L. Michalek1, A. Elabd1, X. Gao1, S. Chen1, C. Xu1, H. Yan1, Y. Jiang1, W. Wang1, Y. Peng1, Y. Zeng1, H. Lyu1, H. Moon1, Z. Bao1, “Tunable 1D and 2D polyacrylonitrile nanosheet superstructures,” ACS Nano 2023, 17, 18, 18392-18401 (September 2023)

Author affiliations: 1Stanford University; 2Argonne National Laboratory; 3Lawrence Berkeley National Laboratory.

This research was supported by the U.S. Department of Energy, Office of Science, Office of Basic Energy Sciences, Chemical Sciences, Geosciences, and Biosciences Division, Catalysis Science Program to the SUNCAT Center for Interface Science and Catalysis. A.P.A. acknowledges support from the National Science Foundation Graduate Research Fellowship Program under Grant No. DGE-1656518 as well as the Stanford Knight–Hennessy Scholarship and the Stanford Enhancing Diversity in Graduate Education Doctoral Fellowship. L.M. gratefully acknowledges funding through the Walter Benjamin Fellowship Programme by the Deutsche Forschungsgemeinschaft (DFG 456522816). Part of this work was performed at the Stanford Nano Shared Facilities (SNSF), supported by the National Science Foundation under award ECCS-2026822. This research used resources of the Advanced Light Source, which is a DOE Office of Science User Facility under Contract No. DE-AC02-05CH11231. This research used resources of the Advanced Photon Source, a U.S. Department of Energy (DOE) Office of Science User Facility operated for the DOE Office of Science by Argonne National Laboratory under Contract No. DE-AC02-06CH11357.

The U.S. Department of Energy's APS at Argonne National Laboratory is one of the world’s most productive x-ray light source facilities. Each year, the APS provides high-brightness x-ray beams to a diverse community of more than 5,000 researchers in materials science, chemistry, condensed matter physics, the life and environmental sciences, and applied research. Researchers using the APS produce over 2,000 publications each year detailing impactful discoveries and solve more vital biological protein structures than users of any other x-ray light source research facility. APS x-rays are ideally suited for explorations of materials and biological structures; elemental distribution; chemical, magnetic, electronic states; and a wide range of technologically important engineering systems from batteries to fuel injector sprays, all of which are the foundations of our nation’s economic, technological, and physical well-being.

Argonne National Laboratory seeks solutions to pressing national problems in science and technology. The nation's first national laboratory, Argonne conducts leading-edge basic and applied scientific research in virtually every scientific discipline. Argonne researchers work closely with researchers from hundreds of companies, universities, and federal, state and municipal agencies to help them solve their specific problems, advance America's scientific leadership and prepare the nation for a better future. With employees from more than 60 nations, Argonne is managed by UChicago Argonne, LLC, for the U.S. DOE Office of Science.

The U.S. Department of Energy's Office of Science is the single largest supporter of basic research in the physical sciences in the United States and is working to address some of the most pressing challenges of our time. For more information, visit the Office of Science website.