Every time we find ourselves desperately searching for a way to recharge our phone or computer before it runs out of power, we encounter the limitations of lithium-ion (Li-ion) batteries. Finding ways to increase the capacity, efficiency, and recharging capabilities of Li-ion batteries is a major challenge that depends upon achieving a deep understanding of how electrode materials respond to repeated charge and discharge cycles and how they store Li-ions. A team of researchers from Texas A&M, Purdue University, TU Darmstadt, and Argonne used the U.S. Department of Energy’s Advanced Photon Source (APS) to probe battery materials at the nanoscale and discovered how the geometry of electrode particles could be the key to getting the most out of Li-ion batteries. The work was published in Nature Materials.

Batteries operate by moving ions back and forth through an electrolyte, but it's an imperfect process. Over repeated cycles, ions can become trapped within the cathode structure and no longer available for charge transport. Also, repeated charge cycles can create stresses that fracture and fragment the material, making it unable to store charge. It all leads to more frequent recharging and ultimately complete failure of the battery. Using V2O5 as a model system, the experimenters studied the phase transformations that occur during repeated Li-ion insertion/extraction in Li-ion battery cathodes with high-energy APS x-rays for operando synchrotron x-ray diffraction (XRD) at the X-ray Science Division (XSD) Structural Science Group’s 17-BM-B x-ray beamline at the APS (an Office of Science user facility at Argonne), and energy dispersive x-ray diffraction (EDXRD) at the XSD Materials Physics & Engineering 6-BM-A beamline, also at the APS.

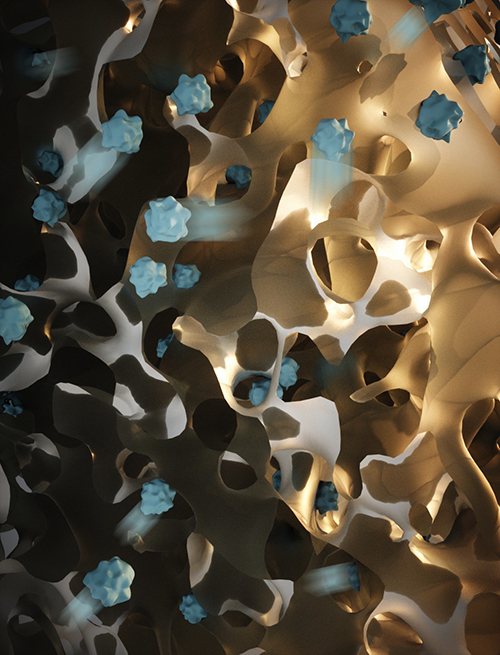

The team compared two cathode architectures, one comprised of bulk a-V2O5 micro-sized platelets and the other of a-V2O5 nanospheres (NS). Despite their identical composition, the electrodes revealed striking differences in their response to repeated lithiation and delithiation. The bulk V2O5 displayed a series of phase transformations during discharge and charge cycles, with increasing phase heterogeneity resulting in capacity fade and substantial stresses. Meanwhile, the NS V2O5 showed no phase coexistence within individual layers, which indicates smooth and homogeneous phase transformations across cycles.

The operando studies show that these differences are directly related to the particle geometry of the cathodes. The phase heterogeneities within the bulk material not only increase stress but also result in stranded areas of lithiation inside the electrode that are unavailable for further cycles, becoming a major factor in capacity fade. The continued homogeneity of the NS material, however, made it capable of complete lithiation and delithiation with excellent reversibility. The geometries of the particles also directly influence their packing and consequent stress accumulation, with bulk V2O5 showing more stress leading to fragmentation.

Another parameter that directly affects the operation and lifetime of Li-ion batteries is tortuosity, which indicates the complexity of the pathways that ions must take as they move in and out of an electrode. The more complex the pathways, the more restricted the capacity and life of the battery. Multiscale modeling allowed greater insights into the diffusion of Li-ions in both the bulk and NS V2O5 material, revealing that the bulk material contained far longer diffusion pathways leading to sharply restricted ionic transport and significantly fewer active sites in contact with the electrolyte. The NS V2O5 displayed much lower tortuosity with greater homogeneity of ion diffusion throughout the electrode.

This work provides a telling demonstration that improving the life and performance of Li-ion batteries isn't just a matter of chemistry, but also geometry. The microscopic shape, size, and packing of cathode particles are key factors in determining battery capacity, lifetime, and efficiency. By using operando powder XRD and EDXRD, the research team forged a fresh approach into the inner workings of batteries that's perhaps been somewhat neglected, but may lead to profound improvements in unlocking the critical potential of Li-ion battery technology, as energy storage solutions become increasingly important.

The next steps for the experimenters will involve investigating other battery chemistries, armed with their new insights into phase progression and ionic transport in intercalation cathodes. The combination of these atomic-level insights into the importance of particle geometries and the development of new battery chemical formulations promises exciting innovations for the next generation of battery technology. ― Mark Wolverton

See: Yuting Luo1, Yang Bai2, Aashutosh Mistry3, Yuwei Zhang1, Dexin Zhao1, Susmita Sarkar4, Joseph V. Handy1, Shahed Rezaei2, Andrew Chihpin Chuang3, Luis Carrillo1, Kamila Wiaderek3, Matt Pharr1, Kelvin Xie1, Partha P. Mukherjee4*, Bai-Xiang Xu2**, and Sarbajit Banerjee 1***, “Effect of crystallite geometries on electrochemical performance of porous intercalation electrodes by multiscale operando investigation,” Nat. Mater. 21, 217. (February 2022). DOI: 10.1038/s41563-021-01151-8

Author affiliations: 1Texas A&M University, 2Technische Universität Darmstadt, 3Argonne National Laboratory, 4Purdue University

Correspondence: * pmukherjee@purdue.edu, ** xu@mfm.tu-darmstadt.de, *** banerjee@chem.tamu.edu

This study is based on work supported by the National Science Foundation (NSF) under DMR 1809866. The authors also gratefully acknowledge support from award no. A-1978- 20190330 from the Welch Foundation. B.-X.X. acknowledges the German Science Foundation (DFG) for funding under project number 398072825. M.P. acknowledges support from the NSF under DMR 1944674. K.X. acknowledges the X-Grants Initiative at Texas A&M University for support of this work. A.M. gratefully acknowledges support from Argonne National Laboratory. P.P.M. acknowledges financial support in part from the NSF under grant no. 1805656). We thank A. Yakovenko for his support at beamline 17-BM of the APS. We also thank J. Okasinski for his help with experiments at 6-BM of APS. Use of the TAMU Materials Characterization Facility and the Texas A&M Microscopy and Imaging Center is acknowledged. This research used resources of the Advanced Photon Source of Argonne National Laboratory under contract no. DE-AC02-06CH11357.

The U.S. Department of Energy's APS at Argonne National Laboratory is one of the world’s most productive x-ray light source facilities. Each year, the APS provides high-brightness x-ray beams to a diverse community of more than 5,000 researchers in materials science, chemistry, condensed matter physics, the life and environmental sciences, and applied research. Researchers using the APS produce over 2,000 publications each year detailing impactful discoveries, and solve more vital biological protein structures than users of any other x-ray light source research facility. APS x-rays are ideally suited for explorations of materials and biological structures; elemental distribution; chemical, magnetic, electronic states; and a wide range of technologically important engineering systems from batteries to fuel injector sprays, all of which are the foundations of our nation’s economic, technological, and physical well-being.

Argonne National Laboratory seeks solutions to pressing national problems in science and technology. The nation's first national laboratory, Argonne conducts leading-edge basic and applied scientific research in virtually every scientific discipline. Argonne researchers work closely with researchers from hundreds of companies, universities, and federal, state and municipal agencies to help them solve their specific problems, advance America's scientific leadership and prepare the nation for a better future. With employees from more than 60 nations, Argonne is managed by UChicago Argonne, LLC, for the U.S. DOE Office of Science.

The U.S. Department of Energy's Office of Science is the single largest supporter of basic research in the physical sciences in the United States and is working to address some of the most pressing challenges of our time. For more information, visit the Office of Science website.