Lithium-ion (Li-ion) batteries have become the dominant energy source for modern electronic devices. They are also used to power electric cars. While gasoline-fueled cars can refill in a matter of minutes, electric vehicles require anywhere from 30 minutes to 12 hours to charge. For wider adoption in electric cars, Li-ion batteries will need to have shorter charging times closer to consumers’ expectations. However, charge rates higher than 1C (a full charge in 1 hour) can quickly degrade performance, reducing capacity, cycle life, and thermal stability. Research at the U.S. Department of Energy’s (DOE’s) Advanced Photon Source (APS) is providing new information about the root cause of this degradation and, thus, clues to a remedy. Their results were published in the journal Energy & Environmental Science.

Lithium-ion (Li-ion) batteries have become the dominant energy source for modern electronic devices. They are also used to power electric cars. While gasoline-fueled cars can refill in a matter of minutes, electric vehicles require anywhere from 30 minutes to 12 hours to charge. For wider adoption in electric cars, Li-ion batteries will need to have shorter charging times closer to consumers’ expectations. However, charge rates higher than 1C (a full charge in 1 hour) can quickly degrade performance, reducing capacity, cycle life, and thermal stability. Research at the U.S. Department of Energy’s (DOE’s) Advanced Photon Source (APS) is providing new information about the root cause of this degradation and, thus, clues to a remedy. Their results were published in the journal Energy & Environmental Science.

During charging in these batteries, lithium ions are extracted (deintercalated) from a lithiated transition metal oxide in the cathode, where these cations form sheets of positive charge between the oxide layers, and inserted (intercalated) between carbon layers in graphite in the anode. During discharge, this process reverses. The graphite and oxide are contained in porous electrode matrices infused with liquid electrolyte. This matrix holds the electrochemically active particles and also provides a conductive path for the electrons to reach current collectors.

Theoretical studies attribute the detrimental effects of high rate charge to lithium metal plating on the graphite, kinetic losses, and lithium ion concentration gradients that develop in both the electrolyte filling the matrix pores and in the porous electrodes. The concentration gradients are problematic for a number of reasons. First, they polarize the cell, lowering capacity by causing the cell to reach its cut-off voltage before all the lithium is fully extracted from the cathode. Second, heterogenous lithiation can lower the anode’s potential, creating conditions that cause lithium plating. Finally, these gradients can facilitate structural stresses within the particles of the active material, causing fracture, and in the electrode matrix at large, causing the coating to peel off the current collector.

The higher the current flowing through the cell, the steeper the lithium-ion gradients, and the greater their detrimental effect on battery performance and life. Although studies have used many means to model these concentration gradients, few have directly measured them within a working battery.

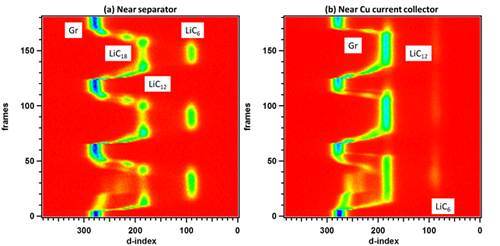

To fill this knowledge gap, researchers from Argonne National Laboratory and the University of Delaware used the X-ray Science Division 6-BM-A beamline at the APS (an Office of Science user facility at Argonne) to peer into a working Li-ion battery using the energy dispersive x-ray diffraction (EDXRD) technique. The team created “movies” of lithiation and delithiation in different sections of the cell. The EDXRD technique allowed them to quantify the lithium gradients that formed in the battery’s porous graphite electrode during cycling at a 1C rate, showing that the conditions for polarization and plating occur even at this modest rate.

The researchers performed their experiments using a standard Li-ion coin cell. Before and during cell operation, the team carried out EDXRD to observe the pristine electrodes and compare them with the conditions that developed during cycling. The x-ray photons from the beamline penetrated through the stainless-steel casing of the coin cell, forming diffraction patterns that identified ordered phases in the graphite layers.

Their results (Fig. 1) show that in the initial stages of charging, the Li content is nearly uniform across the anode. However, as the cell is charged further, a concentration gradient develops, with more lithium present near the electrode surface than at the back. This negative gradient remains the entire time the cell is charging, with lithiation taking time to reach the back of the electrode matrix. During discharge, Li depletion occurs near the surface and gradually spreads into the back of the cell. However, this process does not exactly mirror that of lithiation—during the majority of the cycle, the Li content remains significantly higher in the surface of the electrode. These conditions make Li plating and structural stresses difficult to avoid, even when charging is relatively slow.

The authors note that better knowledge of this imbalance between inhomogeneity in Li insertion and depletion adds insight to why these batteries quickly fail over time at higher charging rates. Eventually, they suggest, researchers may be able to find ways to better design Li-ion cells to protect them from this inherent vulnerability. — Christen Brownlee

See: Koffi P. C. Yao1,2, John S. Okasinski1, Kaushik Kalaga1, Ilya A. Shkrob1, and Daniel P. Abraham1*, “Quantifying lithium concentration gradients in the graphite electrode of Li-ion cells using operando energy dispersive X-ray diffraction,” Energy Environ. Sci. 12,656 (2019). DOI: 10.1039/c8ee02373e

Author affiliations: 1Argonne National Laboratory,2 University of Delaware

Correspondence: *abraham@anl.gov

Support from the U.S. DOE’s Office of Vehicle Technologies, is gratefully acknowledged. The electrodes used in this article are from Argonne’s Cell Analysis, Modeling and Proto-typing (CAMP) Facility, which is supported within the core funding of the Applied Battery Research (ABR) for Transportation Program. We are grateful to our many colleagues (Stephen Trask, Bryant Polzin, Andrew Jansen, Dennis Dees, Jonathan Almer and Andrew Chuang) for their support and guidance during this effort. This research used resources of the Advanced Photon Source, a U.S. Department of Energy (DOE) Office of Science User Facility operated for the DOE Office of Science by Argonne National Laboratory under Contract DE-AC02-06CH11357.

Argonne National Laboratory seeks solutions to pressing national problems in science and technology. The nation's first national laboratory, Argonne conducts leading-edge basic and applied scientific research in virtually every scientific discipline. Argonne researchers work closely with researchers from hundreds of companies, universities, and federal, state and municipal agencies to help them solve their specific problems, advance America's scientific leadership and prepare the nation for a better future. With employees from more than 60 nations, Argonne is managed by UChicago Argonne, LLC, for the U.S. DOE Office of Science.

The U.S. Department of Energy's Office of Science is the single largest supporter of basic research in the physical sciences in the United States and is working to address some of the most pressing challenges of our time. For more information, visit the Office of Science website.