In the past four years, APS physicists and engineers have been actively involved in the development of the innovative horizontal gap vertical polarization undulator (HGVPU) for the Linac Coherent Light Source-II (LCLS-II) x-ray free-electron laser (FEL) project at the SLAC National Accelerator Laboratory. That development work is a natural continuation of a more than decade-long, productive collaboration of the APS and the LCLS. The successful product of this collaboration was the LCLS undulator line designed and built by the APS for SLAC.

The otherwise excellent LCLS undulators have one drawback: the magnetic gap is fixed, and as a result, the undulator has very little ability to tune the FEL x-ray wavelength. The LCLS-II project calls for undulators with an adjustable magnetic gap. Such undulators are quite standard for all synchrotron radiation sources, including the APS. At first glance it seems appealing to take advantage of undulator technology that is so well developed at the world’s storage rings. This approach was chosen by the European x-ray FEL undulator developers and several other facilities followed their lead, including the Lawrence Berkeley National Laboratory (LBNL) undulator team that started their development work for the LCLS-II more than five years ago.

The main challenge for x-ray FEL undulators is the stringent requirement for precise control of the magnetic gap in its absolute value and along the electron beam trajectory. Conventional design, inherited from the synchrotron radiation sources, also leads to quite complicated, bulky, and space-consuming mechanical systems. Although there are no showstoppers in such a design, it does not exploit some advantages that the FEL source brings with its round electron beam and on-axis injection.

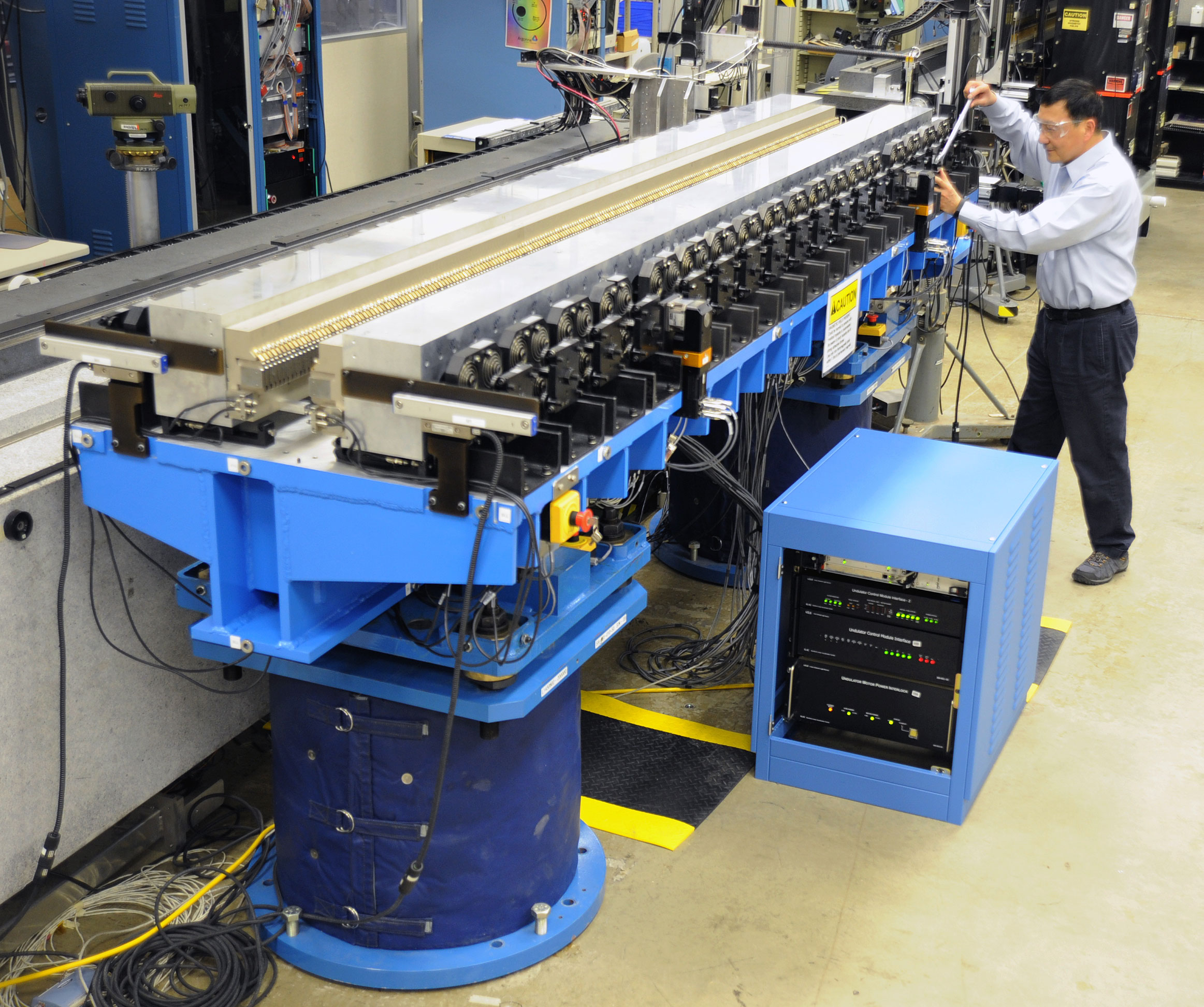

The APS engineers and the APS undulator team suggested an innovative design for the magnetic gap drive mechanism of the HGVPU for LCLS-II. First of all, the overall mechanical system has been designed as gravity-neutral, which results in the rotation of the magnetic gap 90° from vertical to horizontal. Second, the so-called undulator strongbacks – typically heavy, with large cross-section metal plates that hold undulator magnets and poles – have been replaced by much smaller plates. But in order to maintain precise magnet gap control, a spring compensation system was introduced that is distributed along the strongback. This system is capable of dynamically compensating the magnetic force. In principle, magnetic force compensation systems for undulators and wigglers have been known for quite some time. The innovation here came with the use of specially designed springs that would exactly match the gap dependence of the magnetic force. The capability for highly accurate tuning of the compensation mechanism leads to precise control of the gap along the device for all gap settings.

In a period of three years, the APS team designed and built three prototypes of the new horizontal gap vertical polarization undulator with a horizontal magnetic gap. The last one, a 3.4-m-long device with a period of 2.6-cm, recently underwent a set of comprehensive mechanical and magnetic tests at Argonne. It demonstrated remarkable performance and met or exceeded all of the very stringent LCLS-II undulator specifications.

Apart from the fact that this novel device represents a very elegant solution for a daunting mechanical problem associated with the conventional type of undulator, there is another very important advantage to using this device at the x-ray FEL or at future x-ray sources. An undulator with a horizontal gap generates vertically polarized x-rays, and that dramatically improves its utilization for experimentation. Several experiments could be run simultaneously, and bulky mechanical systems with long arms would not “fight” with gravity anymore because they could be placed in the horizontal plane on optical tables.

Another very important advantage of this device is its compatibility with the existing infrastructure in the LCLS undulator line. That leads to significant monetary savings for the LCLS-II project. The performance of the prototype and its advantages over the conventional undulator made it a prime choice for the LCLS-II construction project, where it will be used as a baseline device for the hard x-ray source.

The success of this project is the result of a strong collaborative effort among several APS technical groups from the Accelerator Systems (ASD) and APS Engineering Support (AES) divisions. It started with the concept and preliminary mechanical design originally developed by Emil Trakhtenberg (AES- Mechanical Engineering and Design, MED), expanded after that by a group of University of Wisconsin-Madison engineers, and then brought to the level of production prototype by a group of engineers and designers that included Oliver Schmidt (AES-MED), Kamlesh Suthar (AES-MED), Jie Liu (AES-MED), and Don Jensen Jr. (AES- Design and Drafting), led by Geoff Pile (AES- Mechanical and Interlock Systems) and Pat Den Hartog (AES-MED). Isaac Vasserman and Elizabeth Moog of the ASD Magnetic Devices (MD) Group were responsible for the magnetic design, and Isaac Vasserman (ASD-MD), Joe Xu (ASD-MD), and Nikita Strelnikov oversaw every step of its assembly, and executed magnetic tuning and final overall characterization. Joe Xu introduced several important improvements to the mechanical design and designed the spring calibration system. Nikita Strelnikov, who is doing his Ph.D. work based on this novel undulator, took full responsibility for the spring compensation system. Multiple undulator assemblies/disassemblies have been conducted by Mike Merritt (ASD-MD) and his group of MD technicians: John TerHaar, Susie Bettenhausen, Joe Gagliano Jr. and Eric McCarthy. It must be noted that the project’s success is due to the unwavering support of the LCLS-II Project Director, John Galayda (SLAC National Accelerator Laboratory.

On March 17, 2016, the APS undulator team transferred the complete documentation on the HGVPU to LBNL, where 34 of the devices will be fabricated for the LCLS-II. This novel device designed and built at the APS has a bright future at the LCLS-II and at the next generation of storage ring light sources.

Contact: Efim Gluskin gluskin@aps.anl.gov

This work was funded by the U.S. Department of Energy Office of Science under Contract No. DE-AC-76SF00515. SLAC National Accelerator Laboratory is supported by the Office of Science of the U.S. Department of Energy. The Advanced Photon Source is a U.S. Department of Energy Office of Science User Facility operated for the U.S. Department of Energy Office of Science by Argonne National Laboratory under Contract No. DE-AC02-06CH11357.

Argonne National Laboratory is supported by the Office of Science of the U.S. Department of Energy. The Office of Science is the single largest supporter of basic research in the physical sciences in the United States, and is working to address some of the most pressing challenges of our time. For more information, please visit science.energy.gov.