The dream of a hydrogen economy — a world run on H2 gas, free from the pollution and politics of fossil fuels — may depend on developing an energy-efficient strategy for splitting water into oxygen and hydrogen. The problem is that water bonds are very stable, requiring hefty energy inputs to break. Scientists are eagerly developing catalysts to lower the energy demands, and thus the cost, of H2 production. Yet, they still struggle with the basics, such as what structural properties make a good water-splitting catalyst.

Using measurements from the Materials Research Collaborative Access Team (MR-CAT) 10-ID-B beamline and the X-ray Science Division 12-ID-C,D beamline at the U.S. Department of Energy Office of Science's Advanced Photon Source (APS), researchers analyzed the stability and composition of three small clusters of palladium — Pd4, Pd6, and Pd17 — which are under investigation as potential water-splitting catalysts. They then generated structural models of the catalysts. By combining information about the identity and structure of each cluster with its catalytic activity, the researchers identified a particular Pd-Pd bond that appears to be essential for catalytic function. This research will allow scientists to design better water-splitting catalysts.

Electrochemical water splitting occurs in two distinct reactions: the hydrogen evolution reaction (HER), and the oxygen evolution reaction (OER). In this study, the researchers, from Argonne National Laboratory, the University of Birmingham (United Kingdom), and Yale University focused on the OER, which is currently the least efficient part of the water-splitting process. Past studies showed that platinum metal can catalyze OER, but those materials require a high load of the expensive metal, usually present as large nanoparticles.

In search of more cost-efficient, more energy efficient, and more active options, the current study focuses on palladium catalysts with sizes of less than a nanometer.

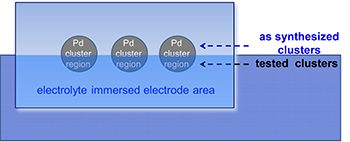

Typically, metallic catalysts are spread somewhat haphazardly onto support surfaces, resulting in unknown distributions of single atoms, clusters, and larger particles. For this study, the researchers isolated size-specific clusters by sending a molecular beam of palladium ions through a mass spectrometer, filtering out all sizes of particles except the clusters of interest: Pd4, Pd6, and Pd17. The clusters were then immediately deposited, separately, on an electrode consisting of a silicon wafer coated with a thin nanodiamond film (first figure).

To test the catalytic prowess of the small palladium clusters, the cathodes were dipped, halfway, into a basic solution, which is the standard medium used in OER. Then, the researchers performed voltammetry, using current as a measure of the turnover rate of the OER reaction. The current generated by the cathode containing Pd4 clusters was no better, and perhaps a little worse, than the electrode alone. However, the Pd6 and Pd17 clusters showed significant activity, with turnover rates that beat those from previous work on Pd metal surfaces and are comparable to those for iridium, the most active metal catalyst for OER.

The next step was to characterize the cluster samples. The researchers brought the same cluster-coated electrodes used in the voltammetry studies to the APS for characterization by grazing incidence x-ray absorption spectroscopy (GIXAS) at beamline 10-ID-B and grazing incidence small angle x-ray scattering (GISAXS) at beamline 12-ID-C,D.

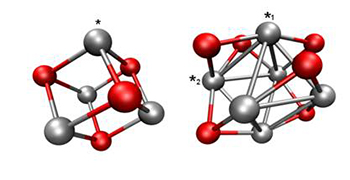

One important observation was that immersed clusters look practically identical to those which were not subject to the water oxidation reaction, suggesting that neither catalysis nor the harsh basic environment changed the structure of the clusters. That stability is key to developing durable catalysts. The measured oxidation states of the Pd4 and Pd6 clusters was used in density functional calculations which determined, for each cluster, the structural configurations (second figure) as well as the free energy for each step of the OER.

Theoretical calculations performed using the high-performance computing cluster at Argonne's Center for Nanoscale Materials suggest that bridging Pd-Pd sites are active for the oxygen evolution reaction (OER) in Pd6O6. Overall, a key descriptor for an efficient OER Pd catalyst is a balancing of binding energy differences with respect to liquid water for each of the important reaction intermediates (O, OH, and OOH). For these Pd clusters, OOH is more strongly bound than the other species, resulting in the observed overpotential. DFT packages Quantum Espresso and VASP were exploited to gain this insight, along with cluster global optimization using the Birmingham Cluster Genetic Algorithm.

The researchers concluded that the pertinent difference between the clusters was the presence of particular Pd-Pd bonds in the two larger clusters, but not in the smaller cluster. They suspect that this bond may be necessary for OER catalysis, suggesting that catalytic surfaces may be hindered by inactive species. The hope is that, with the knowledge of what constitutes an active species, researchers can focus on making water-splitting catalysts using only the best clusters.

— Erika Gebel Berg

See: Gihan Kwon1, Glen A. Ferguson1, Christopher J. Heard2, Eric C. Tyo3, Chunrong Yin1, Janae DeBartolo1, Sõnke Seifert1, Randall E. Winans1, A. Jeremy Kropf1, Jeffrey Greeley1, Roy L. Johnston2, Larry A. Curtiss1***, Michael J. Pellin1**, and Stefan Vajda1*, "Size-Dependent Subnanometer Pd Cluster (Pd4, Pd6, and Pd17) Water Oxidation Electrocatalysis," ACS Nano. 7(7), 5808 (2013). DOI:10.1021/nn400772s

Author affiliations: 1Argonne National Laboratory, 2University of Birmingham, 3Yale University

Correspondence: *vajda@anl.gov, **pellin@anl.gov, ***curtiss@anl.gov

This work was supported by the U.S. Department of Energy (DOE) Basic Energy Sciences Materials Sciences and Engineering, under Contract No. DE-AC-02-06CH11357, with UChicago Argonne, LLC, operator of Argonne National Laboratory. J.G. acknowledges support through a DOE Early Career Award. R.J. and C.H. acknowledge the University of Birmingham North America fund for travel to Argonne. Use of the Center for Nanoscale Materials was supported by the U. S. Department of Energy Office of Science, Basic Energy Sciences, under Contract No. DE-AC02-06CH11357. Materials Research Collaborative Access Team operations are supported by the Department of Energy and the MRCAT member institutions. Use of the Advanced Photon Source at Argonne National Laboratory was supported by the U.S. Department of Energy Office of Science under Contract no. DE-AC02-06CH11357.

The Advanced Photon Source at Argonne National Laboratory is one of five national synchrotron radiation light sources supported by the U.S. Department of Energy's Office of Science to carry out applied and basic research to understand, predict, and ultimately control matter and energy at the electronic, atomic, and molecular levels, provide the foundations for new energy technologies, and support DOE missions in energy, environment, and national security. To learn more about the Office of Science x-ray user facilities, visit http://science.energy.gov/user-facilities/basic-energy-sciences/.

The Center for Nanoscale Materials at Argonne National Laboratory is one of the five DOE Nanoscale Science Research Centers (NSRCs), premier national user facilities for interdisciplinary research at the nanoscale, supported by the DOE Office of Science. Together the NSRCs comprise a suite of complementary facilities that provide researchers with state-of-the-art capabilities to fabricate, process, characterize and model nanoscale materials, and constitute the largest infrastructure investment of the National Nanotechnology Initiative. The NSRCs are located at DOE's Argonne, Brookhaven, Lawrence Berkeley, Oak Ridge and Sandia and Los Alamos National Laboratories.

Argonne National Laboratory seeks solutions to pressing national problems in science and technology. The nation's first national laboratory, Argonne conducts leading-edge basic and applied scientific research in virtually every scientific discipline. Argonne researchers work closely with researchers from hundreds of companies, universities, and federal, state and municipal agencies to help them solve their specific problems, advance America's scientific leadership and prepare the nation for a better future. With employees from more than 60 nations, Argonne is managed by UChicago Argonne, LLC for the U.S. Department of Energy's Office of Science.